IoT and Industry 4.0: Driving the Fourth Industrial Revolution

Hariket Sukesh Kumar Sheth

Hariket Sukesh Kumar Sheth

The Internet of Things (IoT) and Industry 4.0 are two buzzwords that have been floating around the tech world for a while now, and it's time to take a closer look at what they're all about. After all, what's the point of having all this futuristic technology if we can't have a little fun with it?

First things first, let's talk about IoT. It's the idea that every single device we own, from our toaster to our yoga mat, will eventually be connected to the internet. This means that our devices can collect and share data, making our lives easier and more convenient. Want to know how many times you snoozed your alarm this week? Just ask your smartwatch!

Next up, we have Industry 4.0, which is all about transforming the way we manufacture goods. Basically, it's like upgrading from a horse and buggy to a Tesla, but for factories. By connecting all the machines in a factory and automating processes, we can make manufacturing faster, more efficient, and less wasteful. Who knew that the key to a better future was just a few wires and some computer magic?

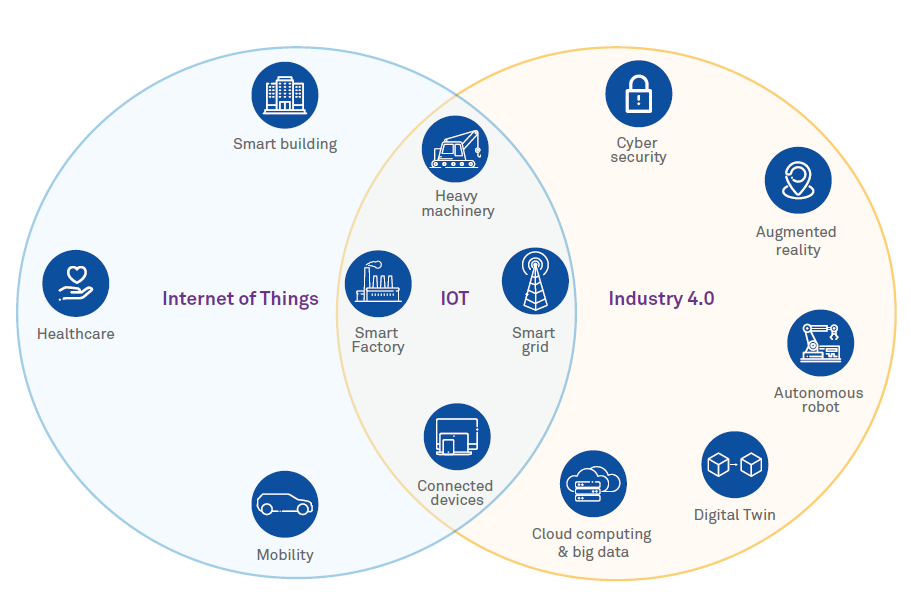

Connection between IoT and Industry 4.0

So what's the connection between IoT and Industry 4.0? Well, think of IoT as the ingredients and Industry 4.0 as the recipe. When you put them together, you get a recipe for revolutionizing the manufacturing industry! With IoT devices, factories can collect data in real-time, making it possible to automate tasks and make better use of data. This leads to increased efficiency, lower costs, and the ability to quickly respond to changes in the market. It's like having a crystal ball that predicts what products you should be making!

IoT and Industry 4.0 - the dynamic duo of the manufacturing world. Think of IoT as the sidekick and Industry 4.0 as the superhero - together, they're making factories faster, more efficient, and more flexible than ever before!

The connection between the two is simple - IoT devices collect data and Industry 4.0 uses that data to automate processes and make smart decisions. It's like having a supercomputer in your factory that knows exactly what to do! For example, an IoT sensor on a machine can detect when it's about to break down and automatically send a maintenance request, saving precious time and avoiding costly downtime.

Latest Updates

Now, let's talk about the latest updates. It's no secret that the world of technology is constantly evolving, and IoT and Industry 4.0 are no exception.

1. EDGE COMPUTING: One of the hottest trends right now is the use of edge computing, which allows data to be processed closer to the source. This is especially useful for IoT devices in remote or hard-to-reach areas, like oil rigs or wind turbines. With edge computing, data can be analyzed quickly and decisions can be made in real-time. It's like having a mini-factory control room right on the factory floor!

- Edge computing allows data to be processed closer to the source, instead of being sent to a remote server for analysis. This is especially useful for IoT devices in remote or hard-to-reach locations, such as oil rigs or wind turbines. With edge computing, data can be analyzed quickly, and decisions can be made in real-time, leading to increased efficiency and lower latency.

5G TECHNOLOGY: Another trend that's making waves is the use of 5G technology. With its lightning-fast speeds and low latency, 5G is perfect for IoT devices that need to communicate with each other in real-time. This means that factories can run even more smoothly, with machines communicating seamlessly and making split-second decisions.

- 5G is the latest and greatest in mobile networks, offering lightning-fast speeds and low latency. This makes it perfect for IoT devices that need to communicate with each other in real-time. For example, in a factory setting, 5G-enabled IoT devices can communicate seamlessly and make split-second decisions, leading to increased efficiency and better decision-making.

- AI AND MACHINE LEARNING: AI and machine learning are becoming increasingly important in the world of IoT and Industry 4.0. By analyzing data from IoT devices, AI can make predictions and identify patterns, allowing factories to make smarter decisions and automate processes. For example, an AI system can predict when a machine is likely to break down and schedule maintenance accordingly, preventing downtime and saving money.

- CYBER SECURITY: As the number of connected devices continues to grow, so too does the importance of cybersecurity. IoT devices are vulnerable to hacking, and it's important to ensure that they are secure to protect sensitive data and prevent unauthorized access. Industry 4.0 is taking cybersecurity seriously, with companies investing in technologies such as blockchain and encryption to protect their networks.

- AUGMENTED REALITY AND VIRTUAL REALITY: Augmented and virtual reality are becoming increasingly important in the world of Industry 4.0, allowing workers to visualize and interact with data in new and exciting ways. For example, a worker can use augmented reality to view real-time data on a machine, making it easier to diagnose and fix problems.

Different Perspective about IoT and Industry 4.0

How is IoT driving the fourth industrial revolution?

Well, let's just say that IoT is the DJ and Industry 4.0 is the dance floor - together they're making the factories of the future come to life! Here's how it works:

IoT devices collect data from the factory floor and send it to the control room, where Industry 4.0 uses that data to make smart decisions. It's like having a party planner that knows exactly what the guests need - when a machine needs maintenance, Industry 4.0 gets the party started by sending a request to the maintenance team. No more downtime, no more delays - just smooth, efficient operation!

IoT devices are like the paparazzi, always on the lookout for information. They gather data on everything from machine performance to energy usage, giving Industry 4.0 a 360-degree view of the factory floor. And with the latest trends in edge computing and 5G technology, the data is analyzed quickly and decisions are made in real-time - it's like having a party that never ends!

AI and machine learning are like the cool kids at the party - they add a whole new level of excitement! By analyzing data from IoT devices, AI can make predictions and identify patterns, allowing Industry 4.0 to make even smarter decisions.

Cybersecurity is like the bouncer at the party - making sure that everything stays safe and secure. With more and more connected devices on the factory floor, it's important to ensure that the data is protected from hackers and unauthorized access. Industry 4.0 is taking this seriously, investing in technologies like blockchain and encryption to keep the party going without any interruptions.

So there you have it - IoT and Industry 4.0, the dynamic duo of the manufacturing world. With their ability to collect data, automate processes, and make smart decisions, they're making factories faster, more efficient, and more flexible than ever before. And who knows what the future will bring, but with these two on the job, I am sure it'll be a dance party like no other!

Advantages, Oh Mighty!

IoT and Industry 4.0 offer numerous advantages that are transforming the way we do business. Here are some of the key benefits:

Increased Efficiency: IoT devices can collect real-time data and provide insights that can be used to optimize processes and increase efficiency. For example, IoT sensors can monitor machinery and alert maintenance teams when they need attention, reducing downtime and improving production.

It's like getting all your friends to help you decorate your house for a party. With everyone working together, you can get the job done faster and more efficiently. That's what IoT devices do in the factory. By collecting data and communicating with each other, they can help optimize processes and make everything run smoother.

Predictive Maintenance: With the data collected by IoT devices, Industry 4.0 systems can predict when machinery will need maintenance, allowing companies to plan and schedule maintenance more effectively. This can reduce the costs associated with unexpected downtime and improve the overall performance of the equipment.

It's like getting a weather forecast before your outdoor party. You know if it's going to rain, so you can plan accordingly. IoT devices do the same thing in the factory. By monitoring machinery and predicting when it will need maintenance, they help companies plan and schedule maintenance more effectively, reducing downtime and increasing efficiency.

Personalized Products and Services: IoT devices can collect data about individual preferences and usage patterns, which can be used to create personalized products and services. For example, an IoT-enabled coffee machine could suggest coffee flavors based on a user's preferred tastes and order history.

It's like your best friend remembering your favorite ice cream flavor. With IoT devices, companies can remember and use your personal preferences to offer customized products and services. For example, an IoT-enabled coffee machine could suggest coffee flavors based on your preferred tastes and order history.

Improved Supply Chain Management: IoT devices can provide real-time tracking and monitoring of products as they move through the supply chain. This can help companies identify bottlenecks and optimize their operations, improving delivery times and reducing costs.

It's like having a GPS tracker on a package you're sending to a friend. You can track its progress and know exactly when it will arrive. That's what IoT devices do in the supply chain. By providing real-time tracking and monitoring of products, they help companies identify bottlenecks and optimize their operations, improving delivery times and reducing costs.

Real-Time Data: IoT devices can provide real-time data about everything from production processes to customer preferences. This data can be analyzed in real-time, allowing companies to make informed decisions and respond quickly to changing market conditions.

It's like having a live update on the number of guests arriving at your party. You always know how many people to expect. IoT devices provide real-time data about everything from production processes to customer preferences. This data can be analyzed in real-time, allowing companies to make informed decisions and respond quickly to changing market conditions.

Improved Safety: IoT devices can be used to monitor hazardous environments and alert workers to potential safety hazards, improving overall safety conditions.

It's like having a designated driver at your party. They make sure everyone gets home safely. IoT devices do the same thing in the factory. By monitoring hazardous environments and alerting workers to potential safety hazards, they help improve overall safety conditions.

Better Customer Experience: IoT devices can collect data about customer preferences and usage patterns, which can be used to create a more personalized and satisfying customer experience.

It's like having your favorite drink waiting for you at the bar. Companies can use the data collected by IoT devices to create a more personalized and satisfying customer experience. For example, an IoT-enabled retail store could suggest products based on your previous purchases and interests.

Challenges, Ofcourse !

Ah, challenges - just like the speed bump at a dance party! But fear not, because with the right moves, we can overcome these challenges and keep the IoT and Industry 4.0 party going strong!

Data Overload: First up, we have the issue of data overload. With all those IoT devices collecting data, it's like trying to dance in a room filled with balloons - you've got to keep your balance! To handle all this data, we need to make sure we have the right infrastructure in place, such as cloud computing and edge computing, to process and store all this information.

Cybersecurity: Next, we have the challenge of cybersecurity. Just like the bouncer at a party, we need to make sure that all the information is secure and protected from those who would like to crash the party! Industry 4.0 is investing in technologies like blockchain and encryption to keep the data safe and secure.

Communication: Another challenge is getting all the IoT devices to talk to each other. It's like trying to get all the guests at a party to mingle and have a good time - everyone has to be on the same page! To solve this, we need to make sure that all the devices are using the same language and protocols, so they can exchange information seamlessly.

Integration: integrating legacy systems with IoT and Industry 4.0. It's like trying to get your grandpa to dance to the latest pop hit - it might take a little coaxing, but it's worth it in the end! By carefully integrating legacy systems with IoT and Industry 4.0, we can ensure a smooth and seamless transition to the factories of the future.

Human Interaction: The fourth industrial revolution relies heavily on automation and machines, but it's important to remember that humans are still a crucial part of the process. Ensuring that the workers have the right skills and training to work with the new technology is a challenge that must be addressed.

Think of it like learning a new dance move. Just like you need to practice and have the right instructor, factory workers need to have the right skills and training to work with the new technology.

Conclusion

In conclusion, IoT and Industry 4.0 are taking the industrial world by storm and transforming the way we do business. Think of it like a superhero duo, with IoT as the "Iron Man" and Industry 4.0 as the "Captain America." Together, they're making industrial processes faster, more efficient, and safer than ever before. From predictive maintenance to improved safety, the benefits of this technology are like a tool belt full of high-tech gadgets that make your work life easier and more productive.

But, as with any superhero duo, it's important to remember to use their powers for good. It's up to us to make sure that the integration of IoT and Industry 4.0 is used ethically and responsibly, to create a better future for everyone. After all, we don't want the industrial world to become the next Thanos, now do we?

In short, IoT and Industry 4.0 are the dynamic duo of the industrial world, bringing their powers to the table and transforming the way we do business. Food for thought: How can we use their powers to create a better tomorrow? The future is bright and the possibilities are endless. Let's use this technology to make the world a better place, one innovation at a time!

Subscribe to my newsletter

Read articles from Hariket Sukesh Kumar Sheth directly inside your inbox. Subscribe to the newsletter, and don't miss out.

Written by

Hariket Sukesh Kumar Sheth

Hariket Sukesh Kumar Sheth

I am highly passionate to explore more in the world of Technology, be it Coding, programming, Software Development, Networking, IoT, IoE, Web Development or App Development. I am pursuing my Bachelor's in Computer Science and Engineering from Vellore Institute of Technology, Chennai. I have been a mentor for TecHacks 2.0 and participated in more than 10 Hackathons till now. I am also fascinated with travelling, exploring and music as well.