Harnessing the Power of FEA and Simulation Software in Engineering

Vishal Sharma

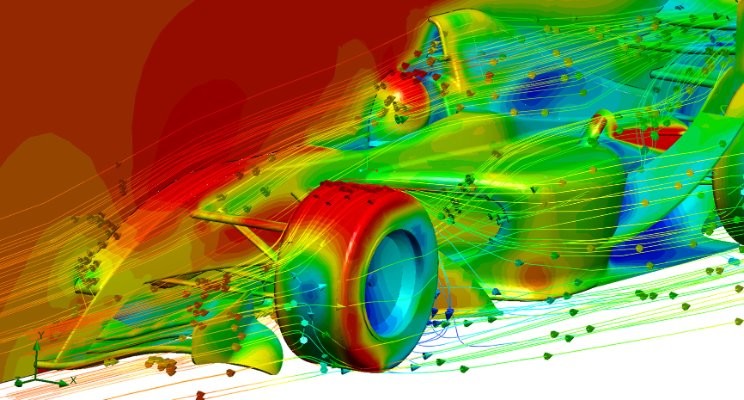

Vishal SharmaIn today's rapidly evolving technological landscape, engineers and designers face complex challenges in developing innovative and efficient solutions across various industries. One of the most powerful tools at their disposal is Finite Element Analysis (FEA) and simulation software. FEA enables engineers to virtually predict and analyze the behavior of structures and systems, saving time, reducing costs, and improving overall product performance. In this blog post, we will delve into the fascinating world of FEA and explore the capabilities and benefits of simulation software in the realm of engineering.

What is Finite Element Analysis (FEA)?

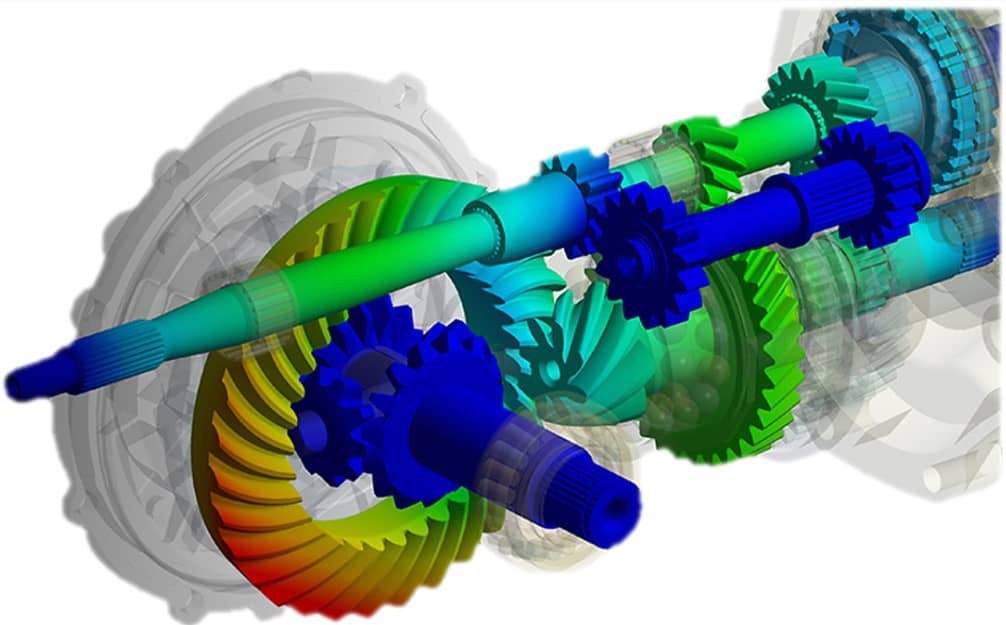

Finite Element Analysis is a computational method used to analyze and predict the response of physical systems to various loading conditions. FEA divides a complex geometry into smaller, manageable finite elements, allowing engineers to simulate and analyze the behavior of the entire system. By applying mathematical equations and numerical techniques, FEA software calculates the stress, strain, displacement, and other physical properties, providing valuable insights into the structural integrity and performance of a design.

The Power of Simulation Software:

Simulation software has revolutionized the way engineers approach design and analysis. By providing a virtual testing environment, it enables engineers to evaluate multiple design iterations, identify potential flaws, and optimize their designs before any physical prototypes are built. Here are some key advantages of utilizing simulation software in the engineering process:

Increased Efficiency: Simulation software enables engineers to streamline the design process by rapidly evaluating and optimizing designs. It reduces the need for expensive and time-consuming physical prototypes, resulting in faster product development cycles.

Cost Savings: By simulating the behavior of a design, engineers can identify and rectify potential issues early in the development stage. This prevents costly design flaws and ensures optimal performance, ultimately reducing production costs.

Improved Product Performance: Simulation software allows engineers to analyze a design's response to different environmental conditions, loads, and constraints. By optimizing the design parameters, they can enhance product performance, reliability, and durability.

Risk Reduction: FEA and simulation software provide engineers with the ability to anticipate and mitigate potential failures or weaknesses in a design. By identifying critical areas prone to stress, engineers can make informed decisions and strengthen the design to ensure safety and minimize risks.

Design Optimization: Simulation software allows for extensive parametric analysis, enabling engineers to explore different design alternatives and optimize the product based on specific requirements. This iterative process helps to achieve the most efficient and robust design solution.

Popular FEA and Simulation Software:

The market offers a wide range of FEA and simulation software, each with its unique features and capabilities. Here are a few notable examples:

ANSYS: ANSYS is a comprehensive simulation software suite that covers various engineering disciplines, including structural analysis, fluid dynamics, electromagnetics, and more. It offers advanced simulation capabilities and a user-friendly interface for efficient analysis and optimization.

COMSOL Multiphysics: COMSOL Multiphysics is a versatile simulation software that allows engineers to simulate and analyze coupled physics phenomena. It supports a wide range of applications, from mechanical and electrical to chemical and acoustics.

Abaqus: Abaqus is a powerful finite element analysis software widely used for structural and multiphysics simulations. It provides robust capabilities for nonlinear analysis, contact modeling, and material behavior.

SolidWorks Simulation: SolidWorks Simulation is an integrated simulation tool within the SolidWorks CAD software suite. It offers a user-friendly interface, making it accessible to designers and engineers for structural, thermal, and fluid flow analysis.

Conclusion:

Finite Element Analysis and simulation software have transformed the field of engineering by enabling virtual testing and analysis of designs before physical prototypes are produced. The ability to accurately predict the behavior of structures and systems enhances efficiency, reduces costs, and improves overall product performance. As technology continues to advance, the integration of FEA and simulation software into the engineering process will undoubtedly play a pivotal role in driving innovation and facilitating the development of reliable and optimized designs. Embracing these tools empowers engineers to push boundaries, overcome challenges, and deliver cutting-edge solutions in a rapidly evolving world.

Subscribe to my newsletter

Read articles from Vishal Sharma directly inside your inbox. Subscribe to the newsletter, and don't miss out.

Written by

Vishal Sharma

Vishal Sharma

I hold a Master's degree in Mechanical Design from BITS Pilani, a prestigious institution renowned for engineering. Over the years, my journey has taken me through various pivotal roles that enriched my technical expertise and broadened my perspective on the industry. I started with New Product Development, delving deep into the intricate nuances of product creation from scratch. As an FEA engineer, I had the privilege to leverage software tools like Ansys and Hypermesh, allowing me to comprehend the depths of Finite Element Analysis and Computational Fluid Dynamics. Beyond these roles, my passion for teaching led me to become an Associate Instructor at Skill Vertex, and since 2018, I've been actively educating a growing audience on YouTube. My proficiency doesn't just lie in theoretical knowledge but extends to practical software skills as well, with hands-on experience in CATIA, SolidWorks, and Tolerance Stack-Up Analysis. One of my notable achievements includes the research and design of differential assembly and driveline components, which was a testament to my dedication and knack for mechanical designing. But at the core of it all, my true desire is to share. I want to bridge the gap between academia and industry by spreading professional knowledge on FEA, 3D modeling software, and tolerance stack-up analysis. I believe in empowering the next generation of engineers with not just knowledge but the wisdom of experience.