Developing an RFID Serialization Plan

Hill Leng

Hill LengTable of contents

- Here are a few key points on RFID serialization management from the GS1 US Guideline :

- Here are the advantages and disadvantages of each serialization model :

- There are a few factors to consider when determining the best serialization model for your company:

- Here are some examples of companies that have implemented centralized serialization models:

- Here are some major challenges companies can face when implementing centralized serialization models:

Item serialization allows you to trace individual products as they move through the supply chain and into the hands of the customer. As you ramp up your Radio Frequency Identification (RFID) tagging solution, you are faced with the decision of how to go about serializing the data encoded in the tags.

Here are a few key points on RFID serialization management from the GS1 US Guideline :

Item serialization allows you to trace individual products through the supply chain and into customers' hands.

There are different approaches to RFID serialization:

• Service bureaus: Third parties manage the serialization and provide pre-encoded RFID tags.

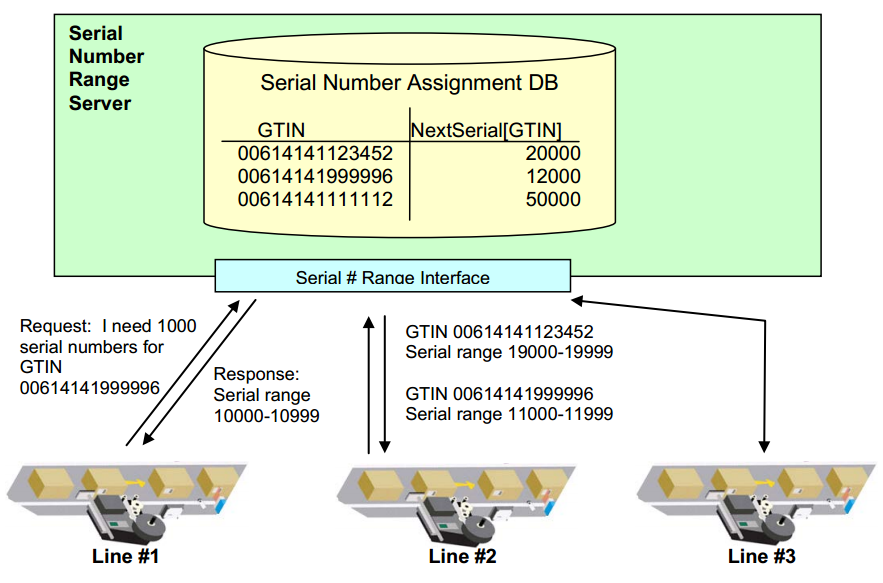

• Centralized/IT-based serialization: A central solution assigns serial numbers in blocks and records encoding details.

• Distributed serialization: Serial number ranges are assigned to different sites and encoding devices.

• Chip-based serialization: Uses the unique transponder ID (TID) to create a serial number.

When developing a serialization plan, you should:

• Understand the serialization model(s) being used

• Reserve a number range for future use

• Assign a number range for trading partners and customers

• Understand customer serialization requirements

There are advantages and disadvantages to different serialization models based on your IT capabilities, factory size, and network connectivity.

You should create a top-level serialization plan that specifies which approach(es) you will use based on factors like:

• What products need to be serialized

• Where serialization will take place

• IT capabilities

• How the plan will evolve over time

GS1 US has an RFID Serialization Management Guideline to explain how to manage the assignment of unique serial numbers to products.

Here are the advantages and disadvantages of each serialization model :

Service Bureaus:

Advantages:

Tags are provided and serialized by a third party, so you don't have to manage serialization

Providers can optimize tag production across locations to lower costs

Disadvantages:

You rely on the service bureau to properly manage serialization

You need documentation from the service bureau on their serialization model

You need to ensure a range of serial numbers is reserved for future use

Centralized/IT-Based Serialization:

Advantages:

Allows you to capture live encoding data which can track factory production and identify counterfeits

Can assign serial numbers while tracking additional details about the tags

May be preferable for large factories/networks

Disadvantages:

- Requires network connectivity to all factory sites

Distributed Serialization:

Advantages:

Doesn't require network connectivity

Serial number ranges can identify where tags came from

Disadvantages:

- May not capture encoding data centrally

Chip-Based Serialization:

Advantages:

Leverages the unique transponder ID to create serial numbers

Offers some degree of randomization

Disadvantages:

- Serial numbers will appear random and not follow a location-device hierarchy

So in summary, the key factors are whether you want to manage serialization internally vs outsourcing it, whether you have the network connectivity and IT capabilities to support a centralized solution, and whether you need the ability to capture detailed encoding data centrally. It depends on your specific needs and capabilities.

There are a few factors to consider when determining the best serialization model for your company:

Internal vs outsourced serialization - Do you want to manage the serialization process internally, or outsource it to a third party? This depends on your capabilities and preferences.

Network connectivity - Can you reliably connect all encoding devices to a centralized system? If not, a distributed model may work better.

Encoding data capture - Do you need to capture detailed encoding data centrally to track production, identify counterfeits, etc.? A centralized model enables this.

Complexity - How complex is your manufacturing network? More localized factories may prefer a distributed model, while a larger network may benefit from a centralized approach.

Cost - Outsourcing serialization to a service bureau may be more cost-effective, depending on the volume of tags needed and your internal capabilities.

Flexibility - Can the model accommodate changes over time? As your needs evolve, a more flexible approach may be preferable.

Control - Do you prefer more control over the serialization process, or are you comfortable outsourcing it? Different models offer different levels of control.

So in summary, I would recommend:

Evaluating your internal capabilities and preferences regarding outsourcing, control, and complexity

Assessing your network connectivity and IT infrastructure

Determining what encoding data you need to capture and how you'll use it

Considering the trade-offs between cost, flexibility and control

Choosing a model that best fits your unique situation now, while being prepared to evolve it over time as needed

These general factors will help guide you in determining which serialization model is best suited for your needs. With enough details about your specific company and use case, I could provide a more targeted recommendation.

Here are some examples of companies that have implemented centralized serialization models:

• Walmart - Walmart requires its suppliers to implement centralized serialization for all items sold in their stores. This enables Walmart to trace products throughout the supply chain for food safety, counterfeit detection and inventory management.

• P&G - Procter & Gamble has a centralized system that assigns unique serial numbers to every product they sell. This has helped them improve supply chain visibility, track production issues and resolve customer complaints more efficiently.

• Albertsons - The grocery chain Albertsons rolled out a centralized RFID serialization system across all of its perishables. This has enabled Albertsons to gain real-time insight into inventory levels, expiration dates and out-of-stock items.

• Coca-Cola - Coca-Cola has a serialization platform that assigns unique identifiers to all of their products. This has helped them reduce product giveaways, identify counterfeits and improve traceability. The system is managed centrally but feeds data to localized plants.

• Unilever - Consumer goods giant Unilever has implemented a centralized item-level traceability system across Europe. This allows Unilever to track and trace individual products through the retail supply chain in near real time.

These examples show that centralized serialization can provide significant benefits for large retail and CPG companies, including improved supply chain visibility, traceability, product tracking and counterfeit detection. However, implementing such systems at scale is a major undertaking, requiring investment in IT infrastructure, encoding equipment and system integration across the supply chain. But for companies with the resources, centralized serialization can drive meaningful operational efficiencies.

Here are some major challenges companies can face when implementing centralized serialization models:

System integration - The process of integrating the centralized serialization system with existing enterprise systems such as ERP, WMS, MES, etc. can pose challenges in terms of complexity and time consumption. It often necessitates the development of custom software solutions and meticulous data mapping.

Network connectivity - Ensuring reliable network connectivity to all encoding locations is essential but can be challenging, especially for global operations. This requires investing in VPNs, wireless networks, etc.

Data management - Managing the large volumes of serialization data generated can be complex, requiring data storage, processing and governance systems to be scaled appropriately.

Equipment upgrade - Upgrading encoding equipment like printers and RFID readers at all locations to support centralized serialization may require significant investment.

Supplier onboarding - Onboarding suppliers, contract manufacturers and logistics providers onto the centralized system can be a lengthy process, requiring education, system access and data integration.

Change management - Convincing plants, facilities and internal teams to transition to a centralized model and change existing workflows can be challenging and requires proper change management practices.

Scalability - The serialization system needs to be able to scale rapidly to meet growth in SKUs, volumes and new product lines over time. This requires a flexible and agile IT architecture.

Cost - The upfront investment and ongoing costs of implementing and operating a centralized serialization system can be substantial for large companies.

Response time - The system needs to be able to respond quickly enough to meet production timelines while also capturing comprehensive encoding data. This requires optimizing processes and technologies.

So in summary, the technical, operational and organizational challenges are significant for any company pursuing a centralized serialization model at scale. Proper planning, change management practices, and a phased approach can help mitigate many of these issues, but companies must be prepared to invest in people, processes and systems to make centralization a success.

Subscribe to my newsletter

Read articles from Hill Leng directly inside your inbox. Subscribe to the newsletter, and don't miss out.

Written by

Hill Leng

Hill Leng

With over 20 years of experience in the RFID IoT industry, I've worked across nearly every stage of the RFID product chain: Chips, Antennas, Bonding, Lamination, Readers, and System Integration. As a seasoned player in both technology and marketing, I'll try to share some best practices and practical tips about RFID to you.