Instructions for Assembling Machines: A Comprehensive Guide

Aleksandr

Aleksandr

Assembling machines, whether it's a simple household appliance or a complex industrial equipment, requires precision, understanding, and a systematic approach. This guide provides a generic overview of the steps and best practices involved in the assembly of machines. While every machine is unique, these general principles can be applied broadly to ensure a safe and effective assembly process.

1. Preparation and Planning

a. Understanding the Manual: Before embarking on the assembly, thoroughly read the manufacturer’s manual. It will provide specific steps, cautions, and perhaps some tips.

b. Tools: Ensure you have all the required tools. Typically, a manual will list the necessary tools. Common tools might include screwdrivers, wrenches, hammers, pliers, and measuring tapes.

c. Space: Choose a spacious, well-lit area to work in. This allows for organization and prevents parts from getting lost.

2. Safety First

a. Protective Wear: Depending on the machine, you might need gloves, safety glasses, ear protection, or even steel-toed boots.

b. Power Precautions: If your machine operates on electricity, avoid plugging it in until the assembly is complete.

c. Work with a Buddy: Some parts might be heavy or tricky to assemble solo. Having a second pair of hands can prevent accidents.

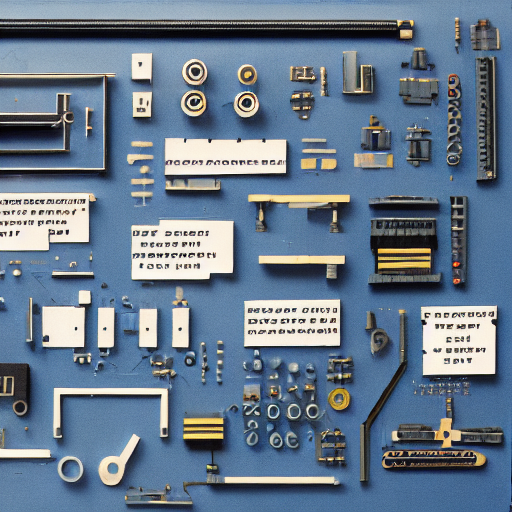

3. Unboxing and Parts Check

a. Inventory: As you unbox, lay out all parts and cross-check with the manual’s list. Ensure no parts are missing or damaged.

b. Familiarization: Familiarize yourself with each part. Understanding the function of each component can simplify the assembly process.

4. Systematic Assembly

a. Step-by-Step: Always follow the manual's recommended sequence. Some parts might need to be assembled before others.

b. Tightening Parts: When joining parts, ensure they're snug but not overtightened. Over-tightening can strip screws or damage parts.

c. Periodic Checks: As you progress, periodically cross-check with the manual’s diagrams to ensure correct assembly.

5. Testing

a. Initial Checks: Before turning the machine on, ensure all parts are secure and in their right place.

b. Dry Run: For power-operated machines, start with a no-load test. This means running the machine without its typical load or function to ensure it operates correctly.

c. Calibration: Some machines may require calibration post-assembly to function optimally.

6. Maintenance and Care

a. Regular Inspection: Periodically inspect the machine for wear and tear. Tighten any loose screws or components.

b. Cleaning: Dust and debris can affect a machine’s efficiency. Regularly clean according to the manufacturer’s guidelines.

c. Storage: If not in use, store in a cool, dry place to prevent damage.

Conclusion

Machine assembly can initially seem daunting, but with systematic steps, proper tools, and an emphasis on safety, it's a manageable task. By ensuring meticulous adherence to the manufacturer's instructions and regular post-assembly care, your machine can have a long and productive life. Remember, the key is patience, understanding, and a methodical approach. If in doubt, always consult the manufacturer or a professional.

Subscribe to my newsletter

Read articles from Aleksandr directly inside your inbox. Subscribe to the newsletter, and don't miss out.

Written by