The Art of Automotive Braking: Where Simplicity Meets Style

Society of Automotive Engineers RUET

Society of Automotive Engineers RUET

Automobile is no doubt a technological wonder that has revolutionized transportation and transformed the way we live and work. It can transport literally everything these days from one place to another at a very short time. But as it is fast, so it is deadly. It can be a lethal weapon if not ensuring proper safety. Automobile safety solely depends on braking system. Since the inception of automotive design, braking systems have been a part of vehicles. “Braking” means to resist. So as braking system which brakes by absorbing the energy of a moving system, the system resists motion. There is a misconception that, the braking system is only applicable in automobiles. Actually, the fact is, a braking system can be designed on any mechanical device where motion occurs, not just on automobiles. But they serve the same purpose and have the same principle.

History of Braking system

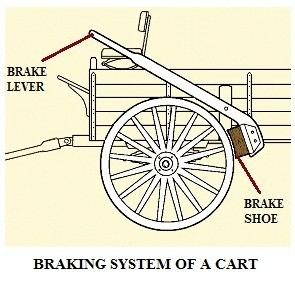

The brake aid and modern braking systems are amazing. Over the years the technological advancements have brought different types and designs to cope with the modern systems. To offer the most effective and cozy braking options, their manufacturers compete with one another as a race. Whoever makes the perfect brake grab the customers. Well, essentially the basic braking mechanisms are still the same. However, going deep into the history, we found that, brakes haven't always been so crucial. When the automobile industry first growing at its top, researchers and innovators focused more on finding ways to start cars rather than stopping them. It’s funny that people than rely on the internal braking of components. Let me decode this simply. Internal braking means the automatic stopping of anything which is in motion, when no power is provided. It is so obvious that, when there is no power the system must stop automatically after some time, because of frictional resistance between internal moving components. The earliest braking system was used is Wooden Block type. The horse carriages and some steam powered automobiles then used this type of brakes. The system is very simple. The driver pulls a lever which forces a block of wood (Similar as brake shoe) against the wheel frame. This causes friction and this friction force resists the wheel rotation.

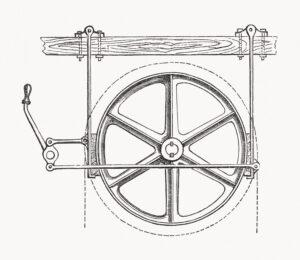

But this mechanism works better with automobiles running at lower speed (less than 20 miles/hour) and is limited to use on wheels with steel rims. Wooden brake pads were not a good option then as it quickly wears out when in contact with the wheel steel rims. Eventually, this technology was superseded by the invention of rubber tires in the 1890s. Then a novel concept for braking was developed in 1899, by a mechanical engineer named Gottlieb Daimler. He then postulated that a drum covered in cables could stop a moving car, if it were fastened to the chassis. Using this concept, another engineer, Louis Renault created the first mechanical drum brake in 1902 [1]. He used brake shoes pressing on the drum, a far more effective technique rather than a cast iron drum wrapped in ropes. This kind of brake has survived until today and this is regarded as the foundation of all contemporary car brakes until today.

The development of modern brakes has been largely influenced by the invention of tires. More specifically rubber tires [2]. Although they are allowed for faster driving and improved comfort on rough terrain, they were incompatible with the era's antiquated brakes. As acknowledged the first automobile brakes were fully mechanical which were powered by the driver’s muscle power. But further technological advancements introduced a new type of brake power system where the power was provided by the hydraulic action. Now-a-days, hydraulic powered braking system is a very trustworthy and reliable name.

Functions of Automotive Braking System

The primary function of the braking system is to slow down the vehicle. When the driver applies the brakes, the system generates friction between the brake components and the rotating wheels, converting kinetic energy into heat energy [3].

This is essential for traffic control, parking, and ensuring safety in various driving conditions.

The braking system plays a vital role in modern vehicle stability control systems. It can apply the brakes selectively to individual wheels to avoid unexpected skidding or rollovers, especially in adverse road conditions like slippery road or unexpected holes or fragmentations in roads.

Basic Components of a Braking System

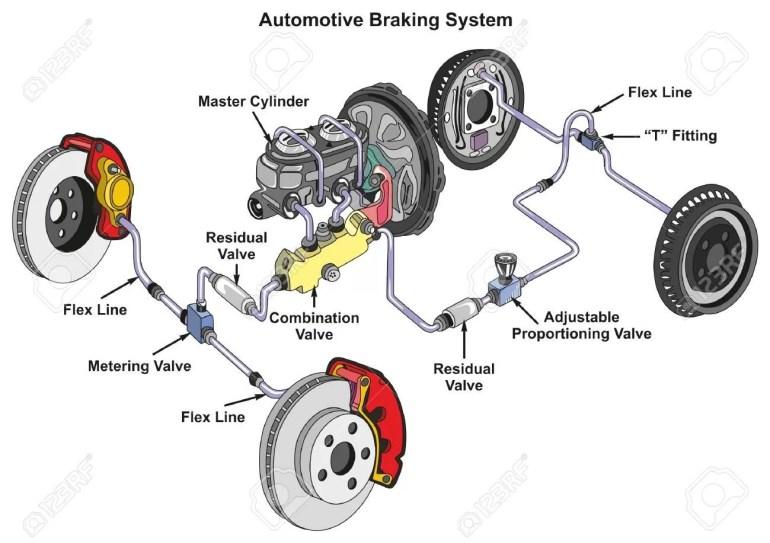

There are many components in modern braking system, but the basic components are same in all kinds of brakes. Let’s have a quick discussion about these components.

Brake Pedal

The brake pedal is the starting part of the braking system that the driver uses to apply force to the system. When the driver presses the brake pedal, the braking starts.

Master Cylinder

The master cylinder is a hydraulic component that converts the force applied to the brake pedal into hydraulic pressure [4]. This pressure is transmitted to the rest of the braking system.

Brake Lines

This component transports the hydraulic fluid (brake fluid) from the master cylinder to the caliper at each wheel.

Brake Calipers (Disc Brakes) or Wheel Cylinders (Drum Brakes)

These are responsible for applying pressure to the brake pads (disc brakes) or brake shoes (drum brakes) to create friction with the rotating brake disc or drum. This friction slows down the vehicle [4].

Brake Pads (Disc Brakes) or Brake Shoes (Drum Brakes)

These are the friction materials that come into contact with the brake disc (rotor) or brake drum. They create friction as soon as the brake pedal is pressed, which results in deceleration.

Brake Rotors (Disc Brakes) or Brake Drums (Drum Brakes)

These are the rotating components that the brake pads or shoes press against to create friction. In disc brakes, the brake rotor is a flat, circular disc, while in drum brakes, the brake drum is a cylindrical component.

Brake Fluid

Brake fluid is a hydraulic fluid that transfers force from the master cylinder to the brake calipers or wheel cylinders.

Brake Fluid Tank

This tank carries brake fluid, which is essential for the hydraulic operation of the braking system.

Types of Modern Braking Systems

There are many types of braking system available these days. But the most common types are:

Hydraulic Braking System

Electronic Braking System

Besides these there are also some advanced braking systems are now in action.

Anti-Lock Braking System (ABS)

Traction Control Braking System (TCS)

Servo Braking System

Air Braking System etc.

Let’s discuss about the most common types and their working principle.

Hydraulic Braking System

In simple word, a hydraulic system refers to the system where a fluid is compressed, and the pressure energy of that fluid is used in that system. So, when the driver presses the brake pedal, the brake fluid transfers from the master cylinder to the brake caliper and pushes the brake shoe or pad against the wheel rotor. This type of brakes are also two types of.

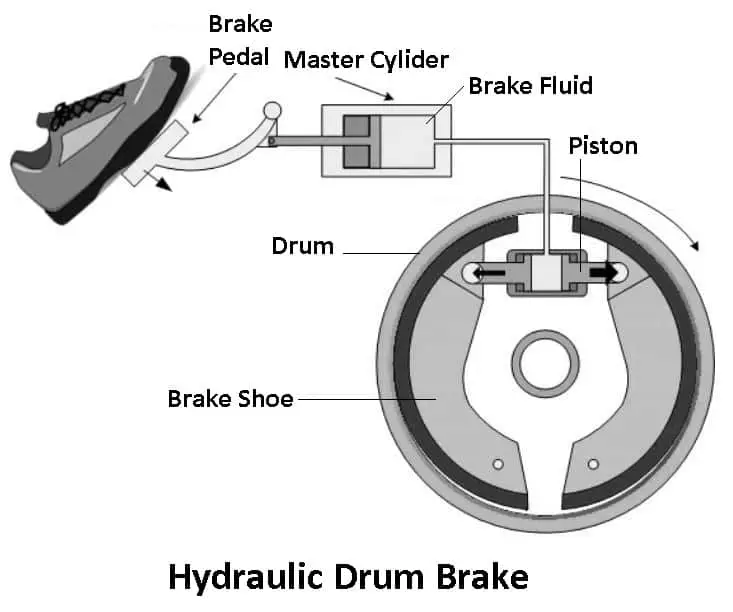

Drum Brake: As shown in the figure when the brake pedal is pressed the brake fluid is pushed by the piston attached to the pedal arrangement. Thus, the fluid transfers from the master cylinder to the hydraulic piston [5]. This fluid pressure pushes the pistons outward, and the brake shoe presses the rotary drum creating a resistant. That’s how drum brakes of hydraulic system work.

Disk Brake: Disk brakes works at the same principle. But the only difference in the disk rotor and brake caliper (holds the brake pad). The hydraulic pressure divided into the brake caliper and presses the pads. The pads resist the rotation of the disk which is attached to the wheel [4].

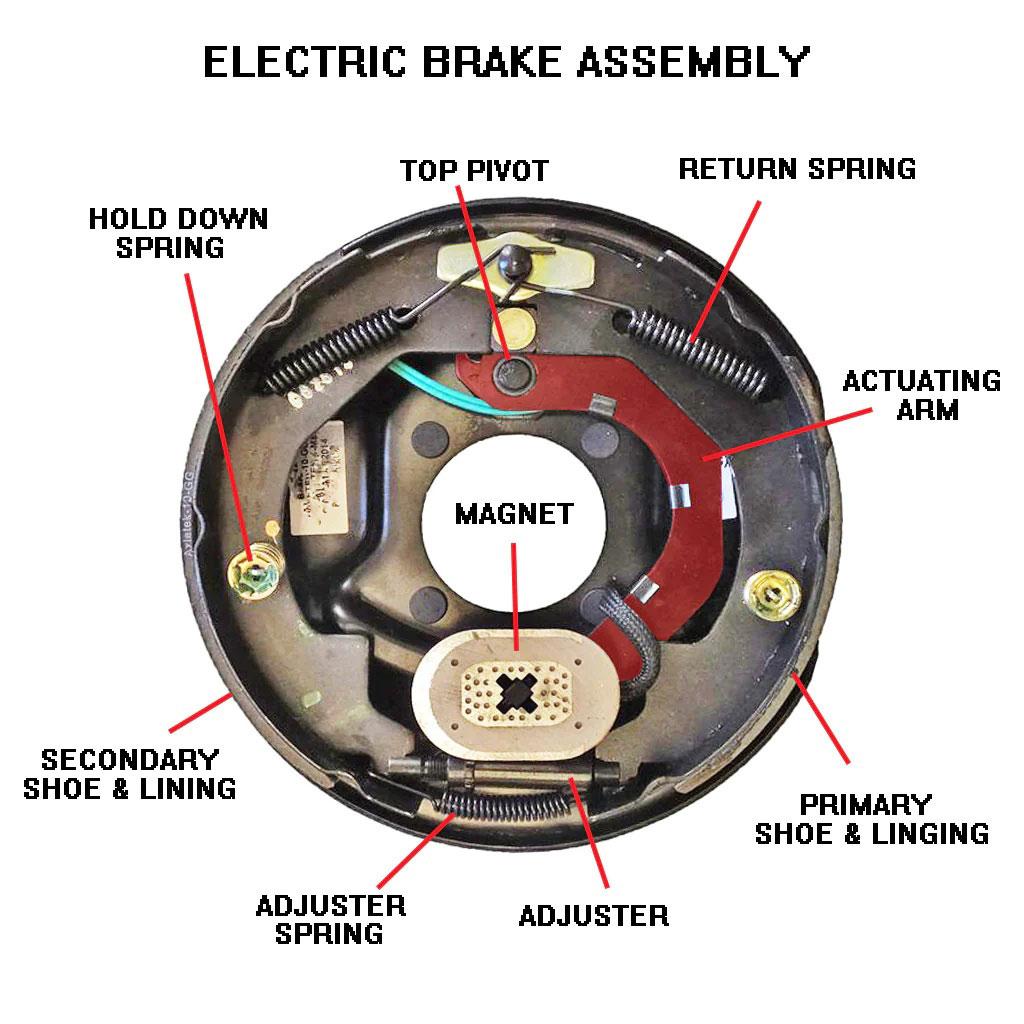

Electronic Braking System

An Electronic Braking System (EBS), also known as an Electronic Brake System, is a modern advancement in automotive technology that enhances the performance, safety, and control of a vehicle's braking system. This enables the possibilities in advanced braking system and proper optimization of it in the modern vehicles. This braking system comes up with the further improvement incorporated with ABS and TCS [6]. It replaces traditional mechanical and hydraulic components with electronic sensors, control units, and actuators, resulting in more precise and efficient brake operation. There are so many benefits of EBS, like-

This kind of braking system need less maintenance.

Furthermore, the braking power is sufficiently higher than conventional hydraulic brakes in comparison to the driver’s braking effort.

This improves the vehicle safety at different running conditions and situations.

The braking principle is basically similar as the conventional one. But the only difference is that the hydraulic brakes use fluid pressure to trigger the brake shoe / pad. But in this case an electromagnet attracts the braking mechanism [6].

Future Aspects

Research and development facilities are still working to create brakes that are even more effective. The components and designs of the braking systems are continually evolving day by day. Additionally, manufacturers are focusing more on minimizing scratchy and vibrational noises. An interlayer in high-quality brake pads, minimizes the vibrations and noises at a great extent. Moreover, the researchers are looking forward to doing some advancement in braking technologies. Those are-

Smart Brake Pads and Sensors System: Future braking systems may incorporate smart brake pads equipped with sensors that can monitor pad wear and brake temperature in real-time. This data can be transmitted to the vehicle's computer system or the driver, enabling more proactive maintenance and improved safety.

Carbon Ceramic Brakes: Carbon ceramic brakes are becoming more common in high-performance and luxury vehicles due to their superior heat resistance and durability.

Lightweight and High-Performance Materials: Ongoing research into materials science will lead to the development of lighter and stronger materials for brake components, enhancing fuel efficiency and performance.

Conclusion

The braking system in autos is critical because it prevents the device from moving when necessary. We have discussed many aspects of the braking system in this article, covering its components and workings and discovered that the system can also be used on a mechanical system with motion. Different types of braking systems are also shown, as well as how they function. I strongly believe this article will help you to get some basic knowledge regarding this topic.

References

[1] ‘THE HISTORY OF BRAKING SYSTEMS’, ABE Performance. Accessed: Oct. 27, 2023. [Online]. Available: ABE Performance

[2] Blog Master, ‘Braking System and the History of it’, Brausen Auto. Accessed: Oct. 27, 2023. [Online]. Available: Brausen Auto

[3] My-cardictionary.com, ‘Brake’, My-cardictionary.com. Accessed: Oct. 27, 2023. [Online]. Available: My Cardictionary

[4] Student Lesson Media, ‘Understanding automotive braking system’, Student Lesson. Accessed: Oct. 27, 2023. [Online]. Available: Student Lesson

[5] ‘Hydraulic Braking System. What is a Hydraulic Braking System?’ Available: Openeo

[6] Lumberjack Camper Trailers, ‘ELECTRIC TRAILER BRAKE SYSTEMS EXPLAINED’. Accessed: Oct. 27, 2023. [Online]. Available: LUMBERJACK

Subscribe to my newsletter

Read articles from Society of Automotive Engineers RUET directly inside your inbox. Subscribe to the newsletter, and don't miss out.

Written by

Society of Automotive Engineers RUET

Society of Automotive Engineers RUET

SAER, an educational organization, is committed to fostering a passion for engineering among RUET students. Its focus extends to the dynamic realms of automotive, aerospace, and commercial vehicles.