Green and Sustainable Driving

Society of Automotive Engineers RUET

Society of Automotive Engineers RUETTable of contents

In the world of automobiles, green and sustainable driving refers to practices and technologies that reduce the environmental impact of automobiles and transportation networks. In order to encourage ecologically friendly and sustainable driving, the automobile industry needs to concentrate on cost-effectiveness as well as how eco-friendly it is. The automobile industry should focus on the environmental effects of cars, starting from manufacturing process. The development of fuel economy (L/100 km) and lowering harmful emissions are two of the most important needs for future automobiles.

What should the automobile industry do to meet the goal of eco-friendly and sustainable driving?

They should focus on reducing dependency on non-renewable sources of energy to produce diesel or fuel, using sustainable materials, and increasing the production of electronic cars. Let’s dive into the world of green and sustainable driving:

Reducing dependency on non-renewable sources of energy to produce diesel or fuel:

It is estimated that humanity will run out of fossil fuels this century. Natural gas may last up to 53 years, oil up to 50 years, and coal 114 years. (When Will Fossil Fuels Run Out? n.d.) So, we need to reduce our dependency on the most valuable asset in the world. We must discover an alternate approach to replacing conventional energy supplies with unconventional energy sources. In that case, e-fuel and the conversion from syngas to diesel or fuel can be great solutions to achieve the goal. In both ways, we can reduce our dependency on conventional energy and make automobiles more eco-friendly. We’ll talk about how they can lessen the demand for conventional energy in this section.

E-fuel

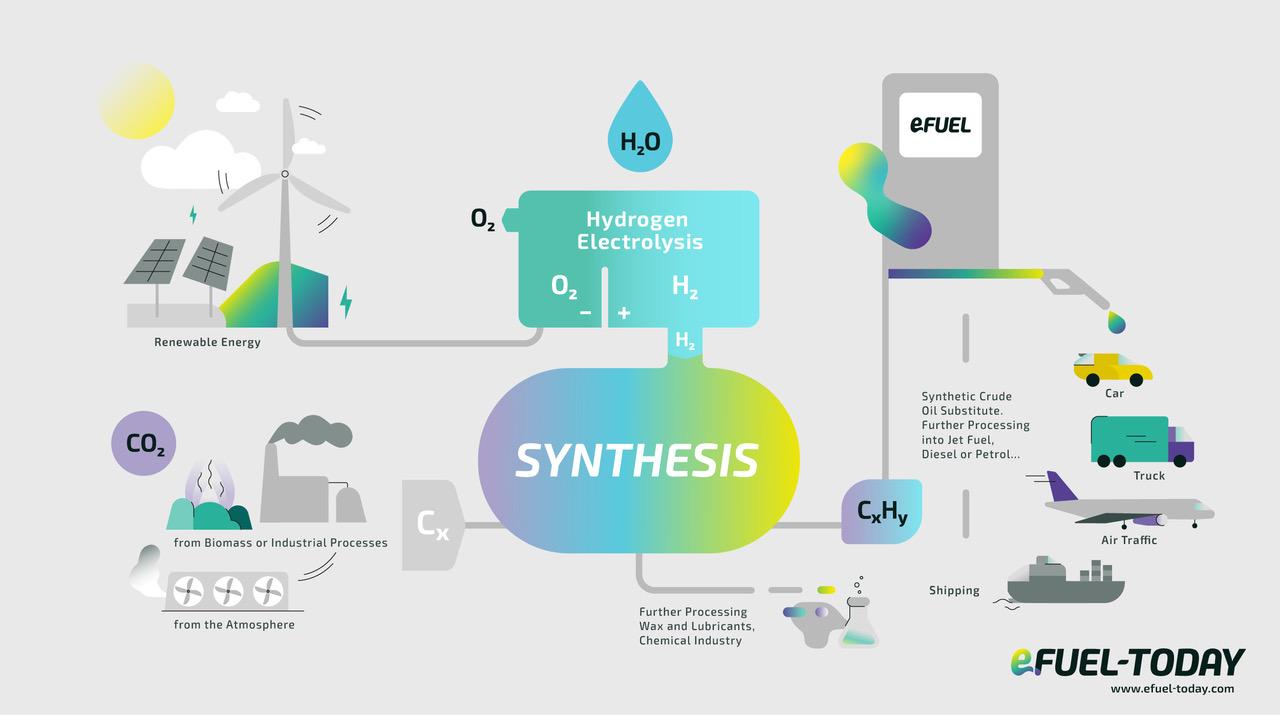

Have you ever heard of creating fuel using only air and water? E-fuel is one solution that can make the impossible feasible. Global concerns often require sophisticated solutions. One of our society’s primary issues is designing a sustainable energy supply and mobility system. Experts agree that only a combination of different technologies will produce a climate-friendly solution. Most crucially, the existing fleet of automobiles, trucks, planes, and ships must also contribute to climate protection. E-fuels have the potential to make up a significant portion of the future renewable energy supply. In some industries, such as aviation and shipping, there are no other options. But what exactly are e-fuels, and how are they made?

Hydrocarbons, which are carbon-hydrogen molecules, are the basic building blocks of any fuel. To make e-fuel, this chemical molecule is simply synthesized. The necessary carbon is either harvested directly from the atmosphere or extracted from industrial facilities. Green hydrogen is produced by breaking down water chemically into hydrogen and oxygen using renewable energy. Renewable energy sources, such as solar, hydropower, and wind, provide the necessary green energy. The synthesis process begins with the production of a crude oil alternative, which can then be processed into petrol, diesel, lubricants, jet fuel, and so on. The key benefits of e-fuels include their ease of storage capacity and transportability, even across great distances, as well as the ability to use existing infrastructure such as trucks, cars, ships, and aeroplanes in a climate-friendly manner. (eFUEL-TODAY, 2023)

Syngas to Petrol or Gasoline

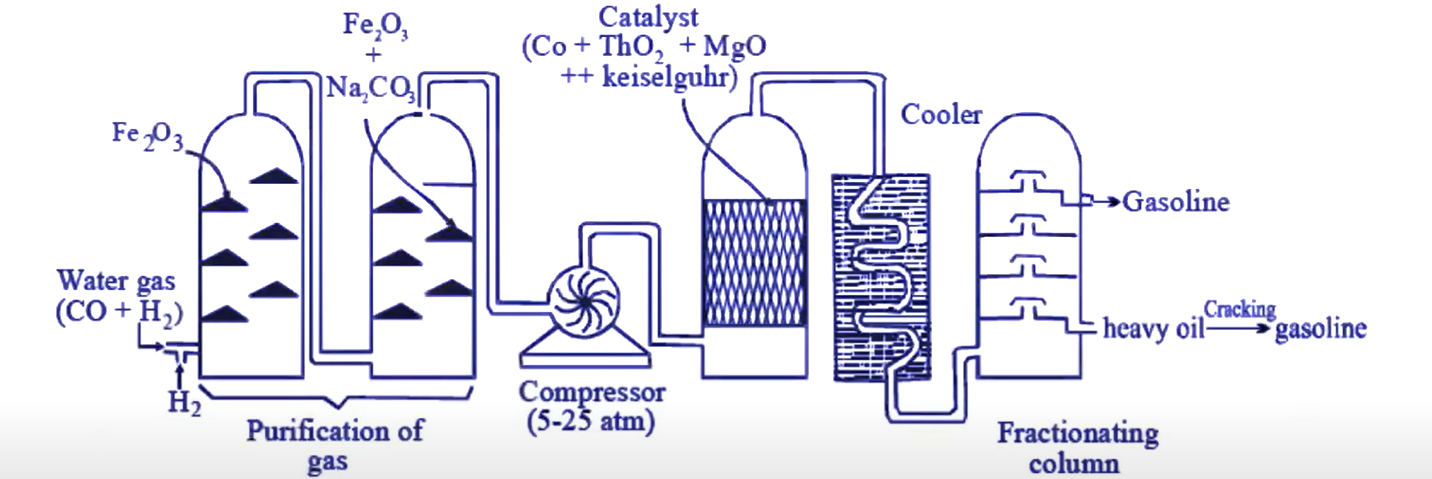

In order to save conventional energy resources and achieve the goal of green and sustainable driving, the conversion of petrol or diesel from syngas can be a good alternative compared to the traditional way. The German scientists Fisher and Tropsch developed a process during the First World War to provide an indigenous source of petroleum products. The process is called the “Fisher-Tropsch Process."

So how does this process work?

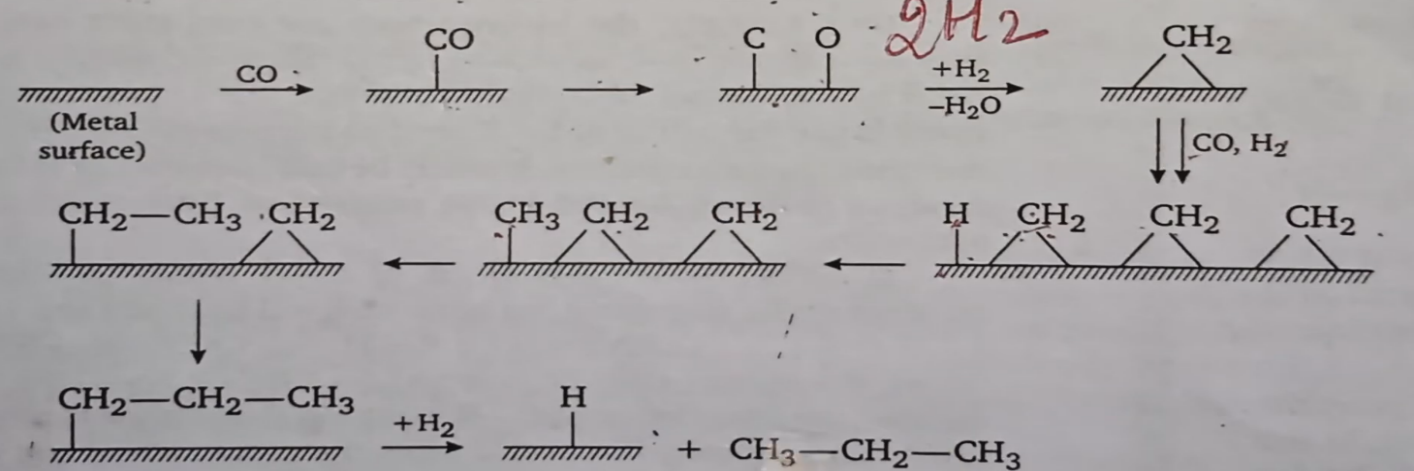

A mixture of water gas (CO+H2) with excess hydrogen is passed through the purification chambers. The iron oxide, Fe2O3, and Na2CO3-containing chambers remove the Sulphur and Sulphur compounds. The mixture, after the removal of Sulphur and its compounds, is forced into the catalyst chamber. At a temperature of about 150°–300°, reactions take place to form saturated and unsaturated hydrocarbons. There is a fractionating column where the gasoline and heavy oils are collected. Later on, after the cracking process of heavy oil, gasoline can be found. (Dr. Rekha Nair, 2020)

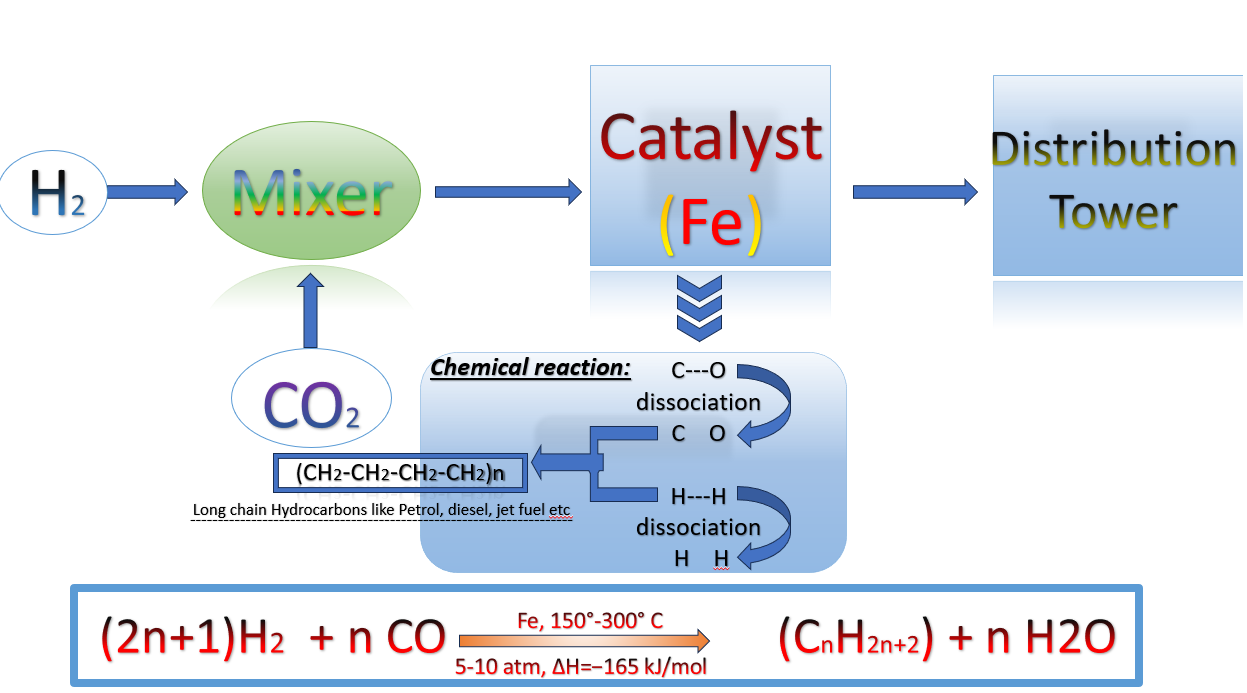

In this Figure, the mechanism of the chemical reaction of the Fisher-Trosph process has been shown.

Chemical reaction:

(2n + 1) H2 + n CO → CnH2n+2 + n H2O

Electronic Vehicles

As nations all over the world gradually stop selling brand-new petrol and diesel vehicles, it is estimated that there will be 145 million electric cars on the road by 2030. Which, at the exhaust, will all be completely emission-free. However, overall emissions from electric vehicles are still less than those from petrol and diesel vehicles. We are left with some challenging concerns regarding the switch to electric vehicles when you take into account the effects their manufacturing process has on the environment and on humanitarian issues.

There are just 20 moving parts in an engine that is battery-powered when we look at an electric car. However, the counterparts for gasoline and diesel have more than 2,000 moving components. It is very dependable and efficient. However, a closer look at the manufacturing process will reveal that the issue still exists. The introduction of electric automobiles is aimed at lowering carbon emissions. However, compared to vehicles fueled by gasoline or diesel, an electric vehicle is thought to require up to 60% more carbon in its manufacturing. This is mostly due to the mining and refinement of rare elements like cobalt and lithium, which are essential for batteries. There is a lot of carbon created throughout this process. For instance, five to fifteen tons of carbon are produced for every ton of lithium that is removed. Long carbon travels, including the global transportation of raw materials, are another effect of battery manufacturing. They are usually sent to China for refinement before being transported back across the globe to be used in automobiles. These are just a few instances that highlight the carbon footprint associated with the electric vehicle manufacturing process. However, the production of electric vehicles raises a plethora of additional environmental, human rights, and geopolitical issues.

When we take into account the fact that, according to some studies, EVs are creating more airborne particles due to tire and brake wear, child labor concerns surround cobalt mining in the Democratic Republic of the Congo, and billions of liters of water are lost from fragile eco-systems during the lithium refining process, electric vehicles can help us lessen our destructive dependency on fossil fuels, but they are by no means a panacea, as we are starting to realize.

Stepping back from the production process reveals a complex environmental problem that extends beyond the cars’ self-sufficiency: EVs are only as environmentally friendly as the power system they run on. For instance, you emit far less CO2 if you drive an electric car in Norway, where net zero-emission hydroelectricity generates the majority of the country’s electricity. However, driving the same vehicle in China, where coal-fired power plants generate the majority of the country’s electricity, may result in emissions equal to consuming two-thirds of a gasoline tank. In fact, according to one study, an automobile running on gasoline released only 24% more CO2 over a 90,000-mile distance than an equivalent-sized electric vehicle (EV) powered by natural gas. Indeed, over the course of their lifetime, EVs produce less CO2 than gasoline or diesel cars, but they cannot achieve the net-zero CO2 emissions that we require if they are not powered by clean electricity. Electric vehicles are unquestionably better for the environment than those driven by gasoline or diesel, despite all the issues we highlighted. However, we must reconsider our existing connection with our cars if we are serious about reducing our emissions. We should demand greener, more integrated public transportation networks and lessen our reliance on personal transportation, rather than trading in our cars for less polluting ones. China already uses 98% of all electric buses worldwide, a sign that although we have the technology, we lack the political will to put it to use. Therefore, instead of waiting for future technological developments to clean up battery manufacturing, we can consider some of the cleaner options that are already accessible, such as car sharing programs and active transportation like walking, cycling, and other types of active travel. One basic issue that needs to be taken into account is just trying to minimize the amount of time we spend in our cars. (The Guardian, 2022)

In conclusion, reducing the negative effects of transportation on the environment requires a commitment to green and sustainable driving. Three important factors that support this endeavor—electric vehicles, e-fuel, and the Fischer-Tropsch process—were discussed in this article.

E-fuels present a viable substitute for traditional fossil fuels, such as synthetic fuels made from renewable energy sources. They serve as a bridge to a more sustainable future in addition to lowering greenhouse gas emissions, particularly for vehicles that still use internal combustion engines.

A breakthrough step toward greener and more efficient transportation is represented by electric cars, or EVs. An increasing number of consumers are finding EVs to be both feasible and accessible because of developments in battery technology and the expansion of the charging infrastructure. They are an essential part of a more environmentally friendly transportation landscape since they reduce air pollution and rely less on finite fossil fuels.

A further aspect of sustainable driving is made possible by the Fischer-Tropsch process, which makes it possible to produce synthetic fuels from carbon sources like industrial waste or biomass. This creative strategy helps promote the circular economy and lessens dependency on conventional fuels derived from petroleum.

Adopting these technologies and practices is essential to building a sustainable and ecologically conscious transportation sector as we negotiate the challenges posed by climate change. The integration of e-fuels, electric automobiles, and the Fischer-Tropsch process presents a versatile strategy that can adapt to a range of conditions. We can all work together to create good change toward a more sustainable and environmentally friendly future for driving on our roads by raising awareness, making research and development investments, and supporting laws that encourage green driving efforts.

Subscribe to my newsletter

Read articles from Society of Automotive Engineers RUET directly inside your inbox. Subscribe to the newsletter, and don't miss out.

Written by

Society of Automotive Engineers RUET

Society of Automotive Engineers RUET

SAER, an educational organization, is committed to fostering a passion for engineering among RUET students. Its focus extends to the dynamic realms of automotive, aerospace, and commercial vehicles.