Vibrating Screen Meshes: Ensuring Optimal Material Flow

shun meng

shun meng

Introduction

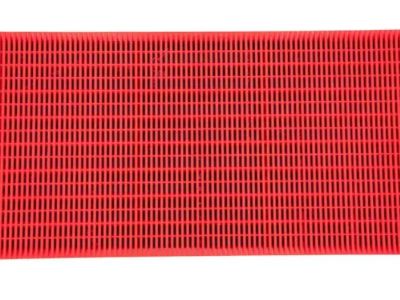

Vibrating screen meshes are a type of tool that helps to sort and filter materials based on their size. They are used in industries such as construction, mining, and agriculture. The mesh is made up of tiny holes that allow smaller materials to pass through while larger ones are held back. This process ensures that the desired material is separated and can be used in the desired application.

The Advantages

vibrating screen have many benefits.

One of the primary benefits is the ability to make material like sure like optimal.

With the use of a screen like vibrating, materials have the ability to efficiently flow more and efficiently, causing higher productivity significantly less downtime.

Furthermore, vibrating screen help to prevent materials from getting stuck or clogging the device, that will lead to expensive repairs.

The Innovation

Vibrating screen meshes have come a way like long the years.

The production process happens to be more accurate, resulting in high-quality products with advancements in technology.

Furthermore, brand materials that are new already been developed that provide durability like increased resistance to wear and tear.

These innovations have actually aided in order to make screen like vibrating more efficient and efficient than previously.

Usage

When utilizing screen like vibrating, it is vital to adhere to safety tips to quit accidents.

Operators must always wear gear like protective such as gloves and security cups, to safeguard by themselves from flying debris.

Additionally, kit should always be inspected frequently to ensure it really is properly maintained and functioning properly.

By following these security precautions, operators will help prevent accidents and injuries face to face.

Applications and Quality

vibrating screen wire mesh are utilized in many applications that are different including splitting various sizes of materials, filtering liquids, and impurities that are removing.

To ensure that these meshes work nicely inside their application like intended is paramount to utilize products that are high-quality are manufactured to industry requirements.

This is made of making use of materials which are often resistant to put up and tear now have already been tested for durability and gratification.

Furthermore, it is critical to utilize a supplier like reputable can provide high quality customer service and support.

Conclusion

In conclusion, wire mesh vibrating screenare a valuable tool for many industries. They have many advantages, including ensuring optimal material flow, preventing equipment clogs, and increasing productivity. By using vibrating screen meshes safely and choosing quality products, companies can help to ensure that their materials are separated and filtered correctly, resulting in higher quality products and happier customers.

Subscribe to my newsletter

Read articles from shun meng directly inside your inbox. Subscribe to the newsletter, and don't miss out.

Written by

shun meng

shun meng

Linyi Jincang Plastic Products Co., Ltd was established in 1995, it is one professional manufacturer of plastic tarpaulin located in Linyi city, which is Chinese famous tourist and logistics city. We are only 3 kilometers away from Linyi high-speed Railway station. There are 1 00 water jet looms, 150 circular looms, 6 drawing machines and 3 coating machines, with advanced production equipment, we can produce 20,000 tons of PE/PP/PVC tarpaulins from 50gsm to 1000gsm and pp woven bag for multipurpose in many different fields such as construction, transportation and agriculture.