Boosting Efficiency in Manufacturing: Software for Quality Control and Traceability

BetaMize

BetaMize

In the dynamic world of manufacturing, maintaining consistent product quality remains a pressing challenge. Key issues such as supply chain disruptions and quality control deviations can hinder efficiency and profitability. However, advanced software solutions offer transformative opportunities to address these challenges effectively.

Current Challenges in Manufacturing Quality

Supply Chain Disruptions:

- Variability in raw material availability and logistics delays can disrupt production schedules, impacting product quality and delivery timelines.

Quality Control Deviations:

- Inconsistent process performance, equipment malfunctions, and human error contribute to quality deviations, leading to waste and rework.

Solving Challenges with Software Solutions

Real-Time Monitoring and Data Analysis:

Sensor Integration: Implement software that integrates with IoT sensors to monitor critical parameters (e.g., temperature, pressure) in real time. This ensures early detection of deviations and proactive adjustments to maintain quality standards.

Data Analytics: Utilize software for advanced data analytics and predictive modeling. By analyzing historical and real-time data, manufacturers can predict potential quality issues and optimize processes accordingly.

Supplier and Material Management:

Supplier Collaboration: Use software platforms to establish and maintain clear quality agreements and specifications with suppliers. This fosters transparent communication and accountability, ensuring consistent material quality.

Material Traceability: Implement robust software solutions for tracking materials throughout the supply chain. This enables quick identification of the source of quality issues, facilitating swift corrective actions and reducing the impact of recalls.

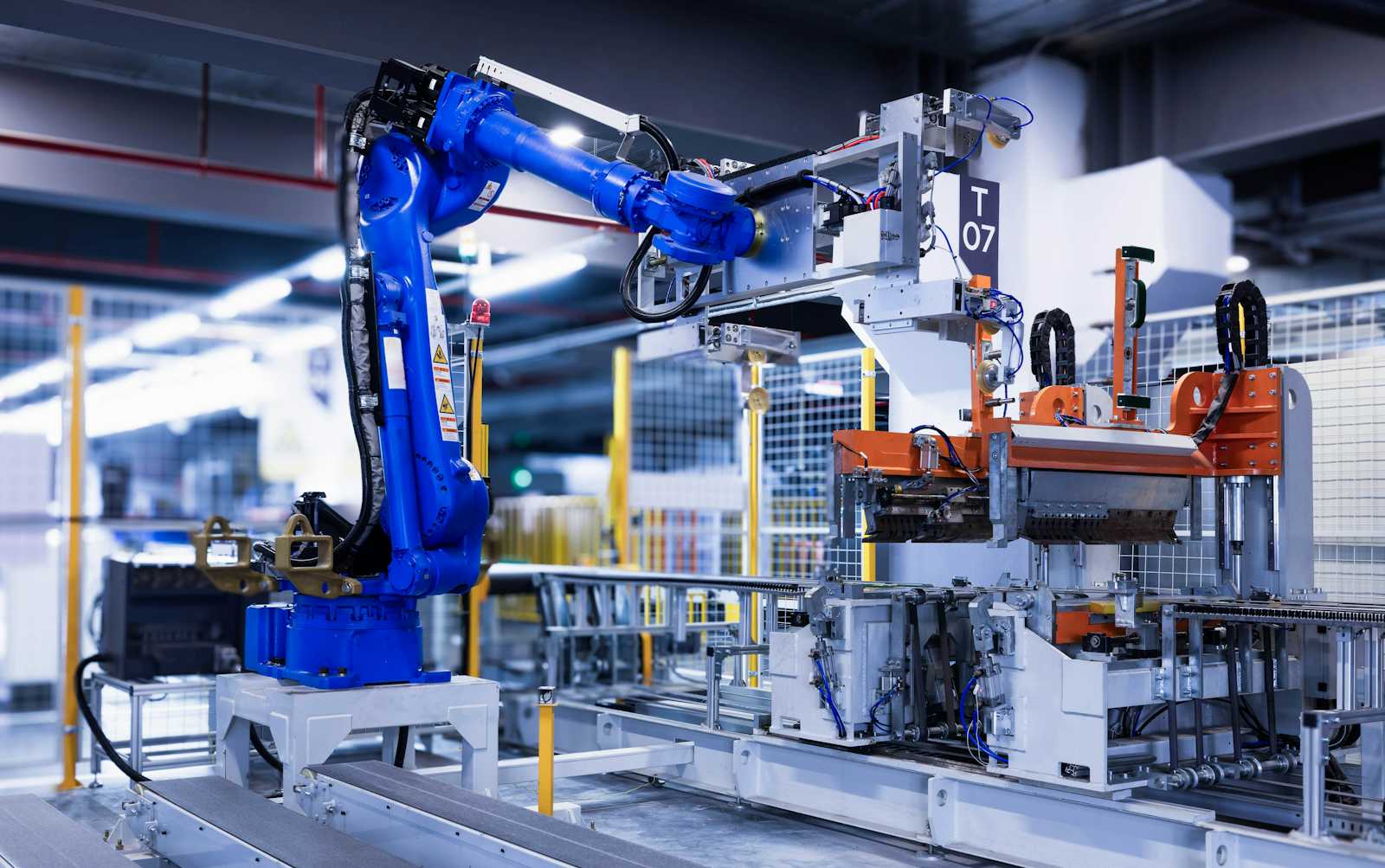

Automation and Quality Assurance:

Automated Inspection: Integrate software with automated inspection equipment and vision systems. This ensures standardized quality checks and reduces reliance on manual inspection, minimizing human error.

Quality Management Systems (QMS): Deploy QMS software to centralize quality-related documentation and processes. This streamlines audits, corrective actions, and continuous improvement initiatives.

How Betamize Can Help

At Betamize, we specialize in innovative software solutions tailored for manufacturing quality management. Our expertise enables manufacturers to:

Optimize Operational Efficiency: Enhance process efficiency and minimize downtime with real-time monitoring and predictive analytics.

Strengthen Supplier Relationships: Improve collaboration and material traceability to ensure consistent quality across production batches.

Ensure Compliance and Accountability: Implement QMS software to meet regulatory standards and maintain high-quality standards throughout the manufacturing lifecycle.

Ready to revolutionize your manufacturing quality? Contact Betamize today to discover how our cutting-edge software solutions can transform your operations. Let’s work together to achieve unparalleled quality assurance and operational excellence.

Subscribe to my newsletter

Read articles from BetaMize directly inside your inbox. Subscribe to the newsletter, and don't miss out.

Written by