ZLD Plant: Maximizing Water Recovery, Minimizing Waste

Taknik Inc

Taknik Inc

Industries are facing increasing pressure to minimize their waste and adopt sustainable practices. One technology that has gained significant traction is the Zero Liquid Discharge (ZLD) plant, which aims to achieve complete wastewater treatment and recycling, leaving no liquid waste to be discharged into the environment..

Here is an overview of how Zero Liquid Discharge (ZLD) plants, Multi-Effect Evaporators (MEE), Mechanical Vapor Recompression (MVR), and Agitated Thin-Film Dryers (ATFD) work:

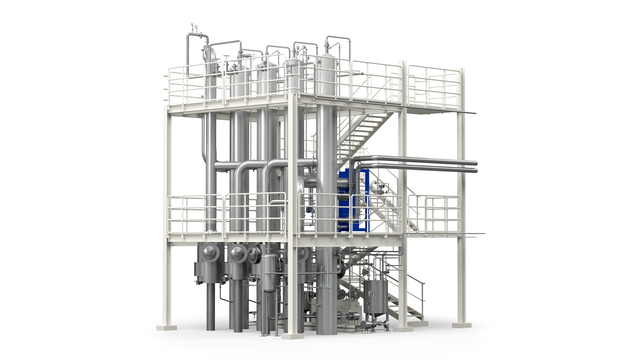

Zero Liquid Discharge (ZLD) Plants:

A ZLD plant is designed to treat industrial wastewater to the point where no liquid effluent is discharged. The goal is to completely recover and recycle all process water. Key components of a ZLD system include:

Pre-treatment: Removal of suspended solids, oils, and grease through processes like filtration, sedimentation, and dissolved air flotation.

Concentration: Multi-effect evaporators, mechanical vapor recompression, or thermal evaporators are used to concentrate the wastewater by evaporating water.

Crystallization: The concentrated brine is then sent to a crystallizer, where the remaining dissolved salts are precipitated and removed as a solid waste.

Drying: An agitated thin-film dryer or other type of dryer is used to further dry the salt/solid waste to minimize the final disposal volume.

Multi-Effect Evaporators (MEE):

Multi-effect evaporators use the principle of reusing the vapors from one evaporation stage as the heating medium for the next stage. This allows for efficient use of energy, as the same thermal energy can be used multiple times. Key aspects:

Wastewater is fed into the first effect, where it is heated and partially evaporated.

The vapor from the first effect is used to heat the second effect, where more water is evaporated.

This process is repeated across multiple effects, with each effect operating at a progressively lower pressure and temperature.

The concentrated brine exits the last effect and can then be further treated (e.g. in a crystallize).

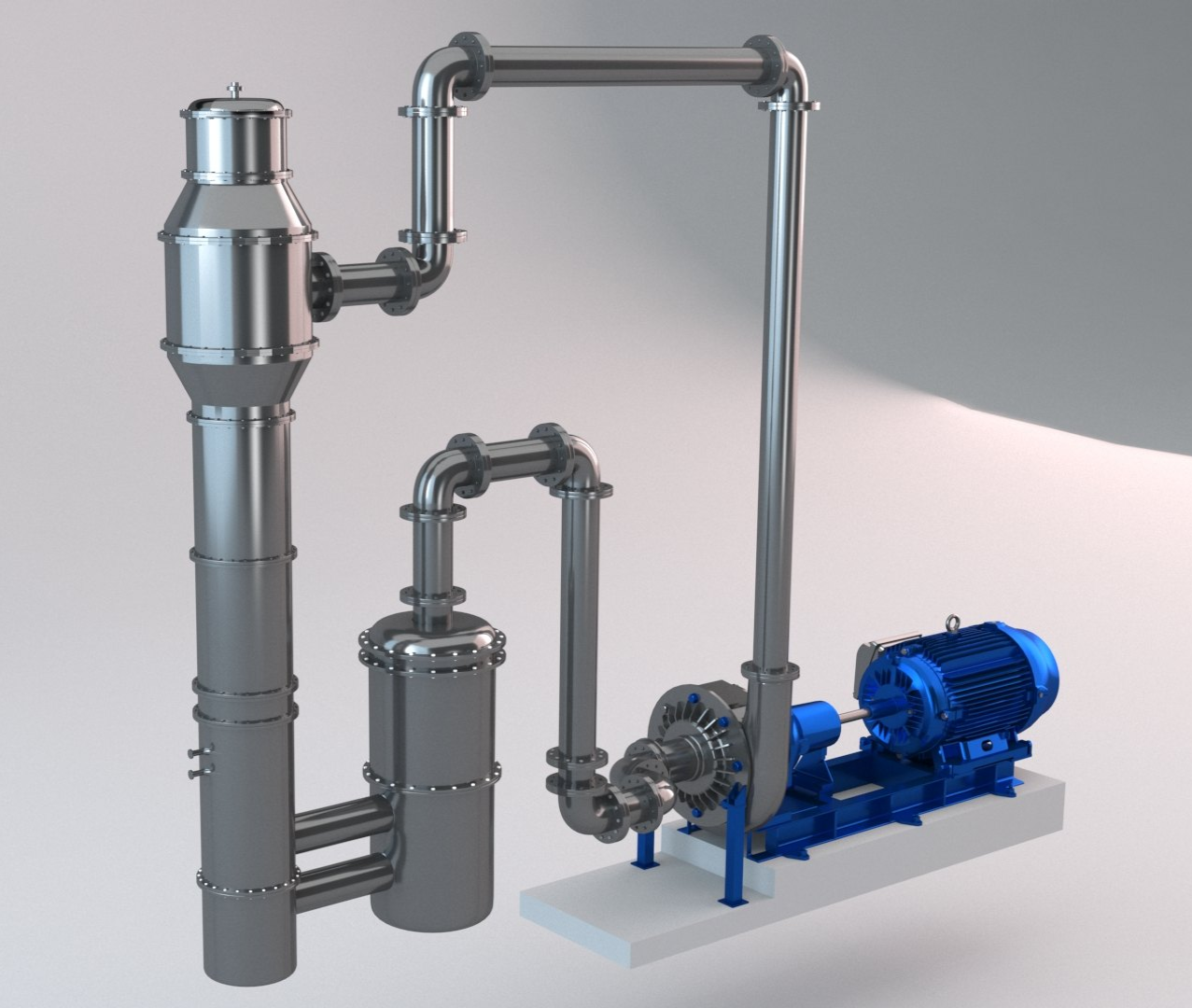

Mechanical Vapor Re compression (MVR):

MVR systems use a mechanical compressor to recompress the vapor generated during evaporation, rather than using steam. Key aspects:

Wastewater is fed into an evaporator, where it is heated and partially vaporized.

The vapor is then compressed by a mechanical compressor, which increases its temperature and pressure.

The compressed vapor is then used to heat the incoming wastewater, allowing the process to be self-sustaining with minimal external heat input.

This allows for highly efficient use of energy compared to traditional evaporators.

Agitated Thin-Film Dryers (ATFD):

ATFD systems are used to further dry and concentrate the brine or salt waste from the ZLD process. Key aspects:

The concentrated brine is fed into the ATFD, where it forms a thin film on the heated surface.

An agitator blade continuously sweeps the film, preventing the formation of dry deposits and ensuring even heating.

The thin film allows for rapid evaporation of the remaining moisture, leaving behind a dry, powdery salt product.

ATFD systems are highly energy-efficient and can achieve very low final moisture content in the salt waste.

Together, these technologies allow ZLD plants to effectively treat industrial wastewater, recover clean water, and minimize the volume of waste for disposal, making them a key solution for sustainable water management.

Subscribe to my newsletter

Read articles from Taknik Inc directly inside your inbox. Subscribe to the newsletter, and don't miss out.

Written by

Taknik Inc

Taknik Inc

Taknik inc is and engineering consultancy services one of the best designs and manufacturer, equipment manufacturer in Bharuch Gujarat, India. we provide high quality of manufacturing equipment for all industries.