Knit to Perfection: The Art and Science Behind Every Loop 🧶✨

Arshin shaikh

Arshin shaikh

Knitting is extremely close to weaving a warm hug with colored threads. Among those precious crafts, simple yarn turns into long, cozy sweaters, fashionable scarves, and many other garments. Among the huge and numerous apparel industries, knitting is of utmost importance because, apart from keeping one warm, it further goes with the fashion designers in expressing their creativity and in creating new styles. It's like a game between yarn and needles, where every stitch narrates some story whether they make a soft pair of socks or a warm sweater.

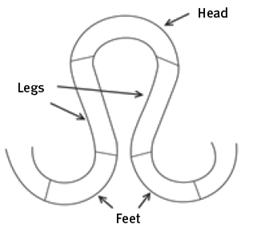

Knitting is the second most used technique in fabric manufacturing where loops are created and passed through other created loops. A knitting-based technique makes fabric. It utilizes knitting needles to make loops which eventually build up into a garment or fabric. There are three significant parts composing each knitting loop:

Head

Two legs

Two feet

The basic principle of knitting can be understood by saying that for every new loop, a previous one has to be used to draw the working yarn through it so as to secure it, thus providing the sturdiness to the fabric. Continuously interlocking the loops forms knitted fabric, granting it elasticity and flexibility.

Whether by hand or with a knitting machine, the basic process is very similar: a new loop is pulled through one that already exists. Technique will vary, but the core principle of making fabric is consistent, so knitting can be both incredibly versatile and remarkably timeless as a method in the textile industry.

History and Advances of Knitting Technology 🏛️🧵

Origins of Knitting

It is not known precisely where knitting originally came from, but most historians believe it originated in the Middle East around the 5th century CE. Among some of the oldest known pieces are Egyptian knitted items-even very fine knit socks-dating back to the early Islamic period, which would approximate the 11th century. It gained widespread acceptance throughout Europe by the 14th century and was primarily promoted in colder regions. The process of knitting, or creating fabric by interlocking loops of yarn, took centuries to develop from a simple handcraft into a huge industrial process that would reflect technological advancements across different eras.

Early Developments

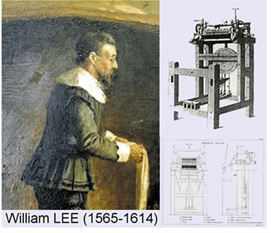

The breakthrough of knitting technology first came in 1589 when William Lee, an English clergyman, could design and add to knitted production the stocking frame, a mechanical knitting machine. Lee's design followed the movement of hands but was opposed. The Queen Elizabeth I refused to give him a patent; she was afraid that the quality of hand-knit stockings produced in so long would deteriorate. Lee's innovation was short-lived, and the measure was eventually implemented across Britain by framework knitters.

The Industrial Revolution and Mechanization 🛠️🧵

Knitting was at a turning point during the Industrial Revolution. In fact, steam-powered knitting machines emerged in mid 19th century with higher production rates and efficiency. The first effort of using steam power for knitting was done by Warners of Loughborough in 1829. Perhaps one of the most significant developments of the knitting industry was the latch needle introduced by Matthew Townsend in 1849. It allowed such a diversity of complex patterns and fabrics to be woven.

Although machine knitting was introduced during this period, it resulted in the commercial occupation of hand knitting diminishing, but its recreational pursuits increased significantly. Some of the prominent factories of Leicester and Nottingham, that branched out during this change, were Corah and I. & R. Morley.

From Finger to Machine Knitting: the Evolution of Knitting 🏆

The word "knitting" originates from the Sanskrit word nahyati, meaning "to bind" or "to tie." This reflects the very essence of knitting as a method of interlocking yarn to form fabric. The development of knitting falls into three main eras:

Finger Knitting 🤲🧶

Around 1000 BC: The earliest method of knitting was carried out purely by fingers, resulting in simple textile fabrics. However the method was highly constrictive owing to the slow movement and the very narrow width of the fabric limited by the length of the fingers.

Hand Knitting ✋🧶

By hand knitting, manufacturers were able to make much more intricate and diversified fabrics, by which quality and variety of knitted products were greatly improved. The skillful knitter was then able to weave around 100 loops per minute, which raised the production and increased the detail in the design.

Machine Knitting (1589) ⚙️👗

The mechanical knitting machine was invented by William Lee. It was the forerunner of a long line of machines designed to increase the speed and consistency with which a product could be produced. A production speed of 500-600 loops per minute was possible with the earliest available model, and later models could do 1,500 loops per minute. This led to large-scale fabric production in the Industrial Revolution. Machine knitting became part of the global textile industry.

Seamless Knitting Technology 💡✨

Seamless knitting technology is an advanced technology developed over the past few decades. It was first unveiled in Europe in the 1984 decade and companies like Italy's Sangiacomo and Israel's Tefron have gone a lot in taking this development forward. Seamless knitting allows mass production where seams are either reduced to near zero or even eliminated completely. This essentially has the advantages of increased comfort as well as fit and also makes the process simpler. On the other hand, automated computer control made seamless knitting possible, which can manufacture different fibers and is well utilized in the production of sportswear and functional clothing.

Contemporary Revolutions 🧵🌐

Synthetic fibers, such as nylon and polyester, joined the ranks in the 1950s, opening further possibilities for mass production of knitted products that are stronger, more supple, and thus easier to manufacture. Digital design tools and software assist designers in creating patterns and swapping techniques from around the world; waves of new creativity can and do surface among industrial and hobby knitters.

Knitting in Fashion and Sustainability 🌿👗

Knitting today is not only for warmth but sustainability and style. Contemporary knitwear designers have increased their efforts on sustainable materials such as organic cotton, bamboo fibers, and recycled yarns in order to minimize the environmental impact. Knitwear itself is durability, flexibility, and adaptability enough to be worn at any formal or casual occasion. Much of the factors increase the more popular way of creating garment with little to no wastage through methods such as seamless knitting in the rise of ethical and sustainable movements in the fashion world.

Conclusion 🎯

Knitting is an old craft that morphed from a simple manual art to highly mechanized and technologically advanced process. The evolution of finger knitting to machine knitting still showcases the versatility of the craft as each innovation supports the longevity of knitting. Modern knitting straddles tradition and innovation by functioning as a bedrock for the fashion and textile industry. Whether for warmth, fashion, or sustainability, knitting is also a popular and indispensable way of creating fabrics that are constantly asking the questions of the boundary of the possibilities.

Knitting is not just a technique, but an art, a science, and a legacy that continues to shape the world of textiles in exciting and meaningful ways. Whether by the comforting hands of a knitter or the precision of a machine, the story of knitting is far from over.

References

https://www.onlineclothingstudy.com/2021/11/a-brief-history-of-knitting-with.html

https://www.linkedin.com/pulse/development-history-advantages-seamless-

https://www.makersmercantile.com/history-of-knitting-a-resource-guide.htm

https://www.textilesphere.com/2024/08/knitting-origin-types-application-and-future.html

https://study.com/academy/lesson/the-textile-knitting-process.html

Subscribe to my newsletter

Read articles from Arshin shaikh directly inside your inbox. Subscribe to the newsletter, and don't miss out.

Written by

Arshin shaikh

Arshin shaikh

Hi! I'm Arshin, a textile science enthusiast and designer with a passion for making fashion both creative and sustainable. I love exploring different aspects of textiles, from knitting to innovative materials, and sharing my knowledge through simple and engaging articles. My goal is to help others understand the fascinating world of textiles and how we can create clothing that's not only beautiful but also kind to our planet. Whether you're a student, a fellow designer, or just curious about how fabrics are made, I hope my blog makes these topics fun and easy to learn about. Join me as I explore everything from knitting techniques to future trends in textile science!