🧶Beginner Knitting Terms Explained: Ultimate Guide to Knitting

Arshin shaikh

Arshin shaikh

Knitting is a centuries-old creativity that has made people warm, creative and comforted. Knitting — a method for constructing fabric through the interlocking of yarn loops, typically by pulling each successive loop through an existing loop. Those loops are intertwined to create the individual rows of a continuous sheet, that part works pretty similar to how knitting does overall. The wide variety of terms and abbreviations can be intimidating for the novice knitter. Aimed at empowering the aspiring knitter to become a confident knitter by mastering knitting terminologies. Knowing these words will also help knitters read patterns, follow instructions and perform a variety of techniques; live life fluently on the needles.✨

🔍 Introduction to Knitting Terminology

Let us discuss a few basic terminologies of the knitting world before we start diving dipper into knitting. Any craft comes with its own jargon, in knitting one of these is knitting abbreviations serving knitters to state what they mean without obstacles. Understanding these terms will help a lot when going through knitting patterns, or watching a tutorial.

In this ultimate guide, we have both the basic and glossary knitting terms that beginners can learn and later use as advanced knitters. All we need is a yarn and two needles, so let's do this!

📌 Basic Knitting Terms

Knitting: Knitting is a way to fabricate with interlocking stitches, usually done by pulling every new loop through and existing one. These interconnected loops are designed to form a continuous sheet, in exactly the same way that knitting works.

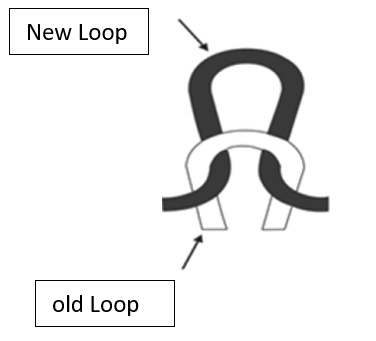

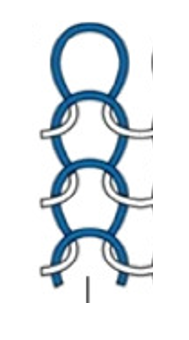

Open Loop: An open loop in knitting, means the at bottom of your loops yarn is not crossing. Therefore you do not get the relaxed structure, as in picture if loops at 3. accomplished but with remaining legs of loop separate Blame an open loop for a looser, more flexible fabric.

Closed Loop: In a closed loop the legs of the loops cross over one another so that this may be fully close. The loop is formed as a safe and continuous structure when the yarn strands cross, which in turn helps to keep knitted fabric stable.

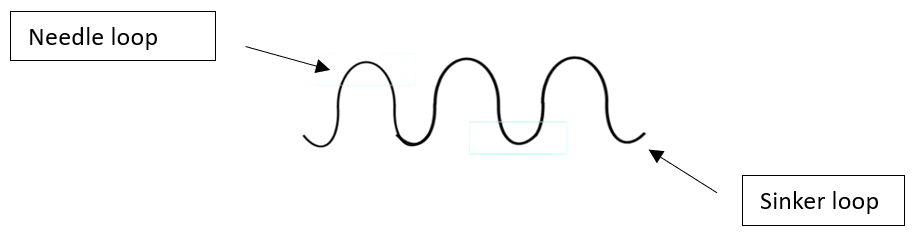

Needle and Sinker loop: The tip of this loop is head inflatable a bit on the top, that area will be considered as through needle rounding. The sinker loop is the bottom part of this, formed at either end or base when they move down and whilst a cylinder assembles new loops.

Face Loop: A face loop is a chain of stitches that leads to the face side (the correct or front) surface. Generally, this type of loop is visible on front side of fabric and it add in the texture and design.

Back Loop (Bl): It is a loop that points to the back of fabric. The catch is that this loop would typically hide on the wrong side of your fabric and could affect how smooth or textured it looks from the back.

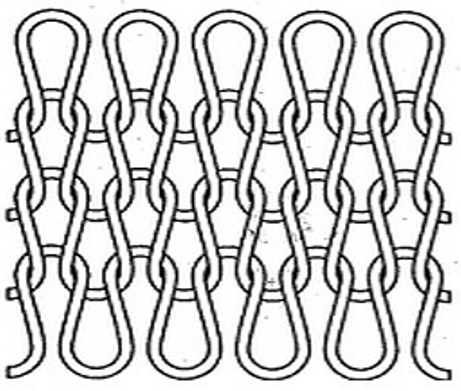

Weft knitting: In the process of weft knitting, loops started to be formed via needles that knit yarn back and forth through a fabric. Each weft yarn is fed at 90 degrees to the fabric making process. This method allows the fabric to hold its shape but still be flexible, like fabrics found in t-shirts and sweaters.

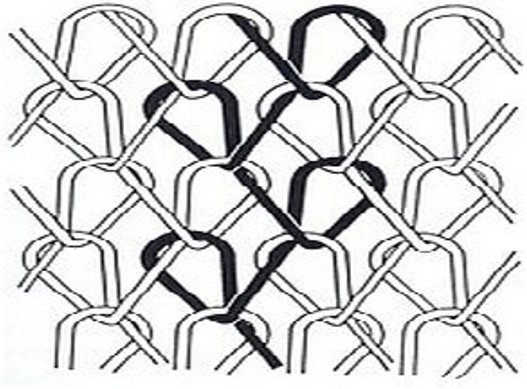

Warp Knitting: Warp knitting is where loops are made with needles which knit a series of warp yarns that run parallel to the direction in widthwise production of fabric. By this process, more stable and stiffer fabrics which are not so much stretchable as in the case of weft knitted fabric is obtained.

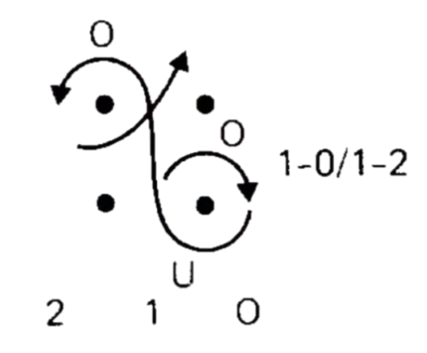

Course: Course is a horizontal row of loops made into the knitted fabric.

Wale: Wale is the name used for a vertical column of loops.

Course Density: The lengthwise row of loops across a fabric (could be horizontal or vertical depending on the arrangement).

Wale Density: The number of those wales (vertical columns) per inch or cm.

Stitch Count: The total number of loops in an area fabric (either per sq-inch or cm). That is, it can be derived from the course density and wale density.

Over and Under Laps:

Over Lap: the yarn that passes above or overlaps with the needle.

Under Lap: The yarn which takes back two over laps is called under lap.

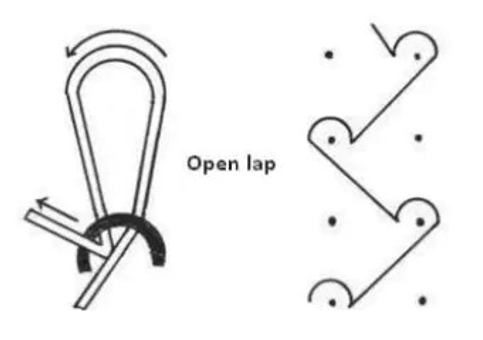

Open Lap: In a particular lap the over and under laps move apart in both directions thus having an open structure of the knitted fabric.

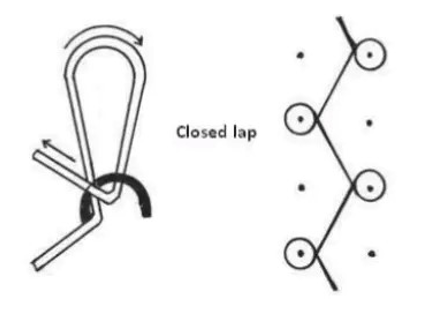

Closed Lap: When the over and under laps go in the same direction they form a closed lap which is tighter.

Single Jersey: If the loops are formed only one side then this type of fabric is known as Single jersey. This fabric is usually a good lightweight, with the right side smooth and textured back.

Double Jersey: When loops are formed on both sides then the fabric is called double jersey. It is usually thicker and heavier than single jersey, making it best-suited to similar structured garments.

Gaiting: Gating refers to the specific configuration of needles in a knitting machine, which identifies on how fabric is formed and type of fabric we produce.

Direct Gaiting: Needles on the knitting machine are placed directly opposite to each other in position. This pattern is structured in a way that impacts the shape of those loops and leads to an even fabric structure.

Indirect Gaiting: Indirect gaiting involves positioning the needles not to face directly across from each other. This configuration forms a different loop shape and may affect the hand or feel of the fabric.

Grain: Any direction in the fabric parallel to either course (the horizontal rows) or wale (vertical columns). It indicates where to match the loops in the fabric.

Off Grain (Bias): Any direction in the fabric that is not parallel to a course or wale. Bias cut fabrics are very stretchy.

True Bias: True bias is the direction which is perfectly diagonal to both the course and wale at an angle of 45°. The true bias of the fabric presents the most stretch.

Selvedge Fabric: The selvedges of these fabrics are produced on a flat knitting machine with distinctive, intact and very clean edges on both sides. The selvedges safeguard the fabric from fraying and they add a professional finish to your work.

Tubular Fabric: A tubular fabric is a continuous tube of cloth that is produced using circular knitting machines. A fabric without any seams that is popular in t-shirts and similar items.

Purl: The reverse of a knit stitch is purl, and it's abbreviated to P. This is different from knitting in which the needle goes through front to back. The purl stitch one of the basics is a must learn skill that makes stockinette stitches and adds some texture in your knitting.

Cut Edged Fabric: When tubular fabric is cut along its length, it forms flat pieces of fabric. This is referred to as cut edged fabric.

GSM (Grams/Meter): GSM is the fabric weight of one square meter in grams. It plays an important role in knowing the thickness and fabric quality of the knitted fabric.

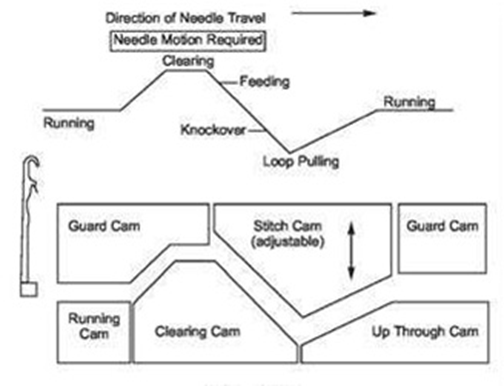

CAM: CAM stands for a vital mechanical part of knitting machines. This translate the rotary motion of the machine into the required reciprocating action which is needed for either needles or any other knitting components. As far as we concern the knitting technology, there are different types of CAMs used in knitting:

CAM for Engineering: It is used in controlling different mechanical functions.

CAM for knitting CAM: State specifically built to control the actual needling process.

Needles: These are unique metal parts that help in drawing the new loop through the old one to make a knit fabric. Needles are used according to the type of knitting:

Bearded Having Needle: (passive needle); An early kind of needle

Latch Needle: Also known as automatic needle, it has a latch mechanism which makes it self acting.

Compound Needle: This is a high speed needle having to parts which allows fast knitting.

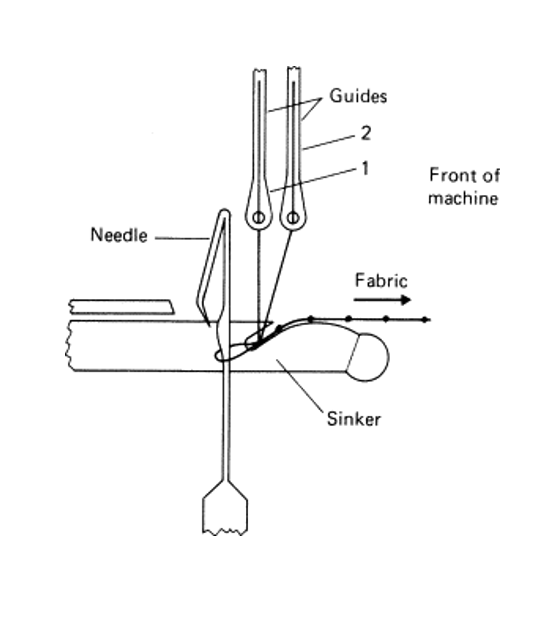

Guide: A guide is an iron plate, at the bottom of which there is a hole through which yarn travels. At the top end they are kept together and separated apart with respect to the gauge of the machine. They serve to guide the yarn correctly while knitting.

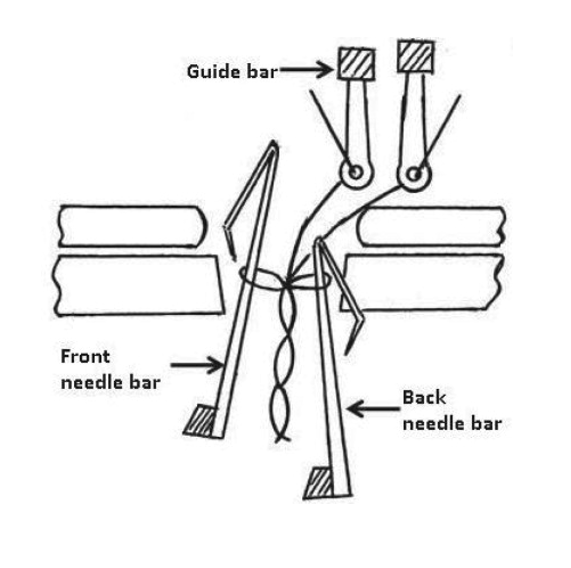

Guide Bar: Guide bar plays an essential role in a warp knitting machine and is known for guiding the warp yarns towards the knitting (or latch) needles. This controls the movement of guides and helps in creating various patterns on knitted fabric. The guide bar allows to place the yarn exactly where it needs to be, giving way for precise knitting and pattern formation.

Gauze: Gauze is denser, and means that there are more needles on the knitting machine in a given distance. This indicates how fine or coarse the fabric will be. The higher the gauge, the more fine-gauge needles are used to create a tighter, more delicate fabric. On the other hand, a smaller gauge means that larger or bulkier needles have been employed to create an overall thicker, more openly knit fabric. What is called "gauge" can also depend upon the "cut" or tension. It is an important parameter that plays a direct role in the textural, weight and visual properties of the fabric on both flat and circular knitting machines. For gauge, one merely counts the needles on a machine’s needle bed.

Feeders: A feeder is the yarn guide located near the needles, and cover complete annulus of knitting zone. Their main job is to guide the yarn into the needle hooks. The feeders are also essential to actuating the needle latches to hold needles in an open position while passing over their clearing position. Maintaining such precise latch control during feeding is critical to loop consistency and subsequently needle efficiency.

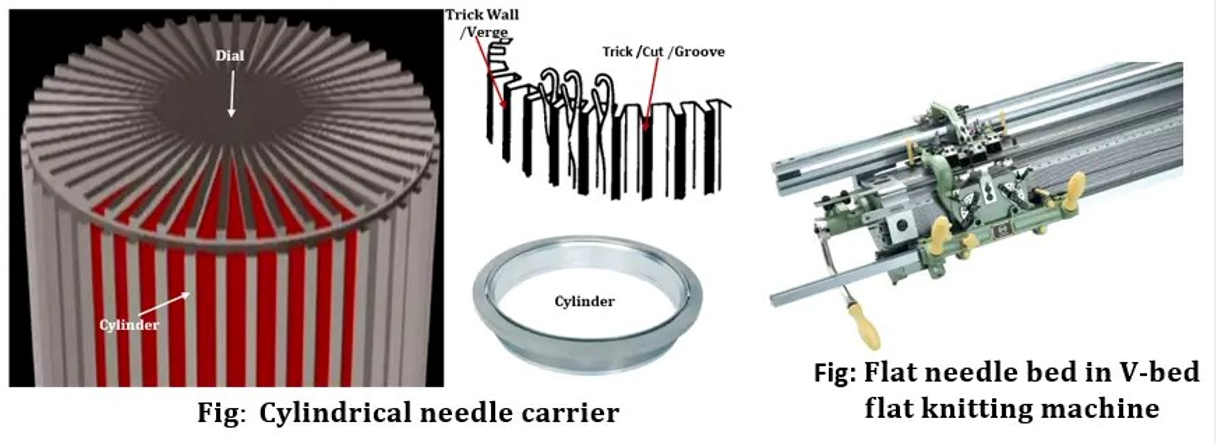

Needle Bed (or Needle Carrier): in a knitting machine, the part where the needles are situated or mounted. This is the substructure above which the needles exist, enabling them to raise and lower as needed for knitting. Inside the slots (called "tricks") of the needle carrier, there is space for the movement of the needles.

Cylindrical or Circular: The needle carrier in circular knitting machines is cylindrical or circular, due to which the needles can form loops when the cylinder rotates. Such a setup is suitable for the manufacture of tubular fabrics.

Flat: The needle sue caries is flat in these types of round knitting machines with the needles arranged linearly. These needle carriers are used to produce flat fabrics, and the knitting is performed back-and-forth in a more reciprocating motion as opposed to the continuously circular motion associated with cylindrical machines.

Double Faced Structures: Formed in weft and warp knitting with two sets of independently controlled needles. The first set of needles has hooks that face the opposite direction of the other set. Thus, the loops that both needle sets pull from the same yarn are pulled in opposite directions and create fabric in between them. The fabric displays the face loops of one set of needles on one side and the face hooks of another set on the other side. Inside the fabric, sinker loops or under laps hold the two fabric faces together, concealing reverse stitches.

Balanced Structure: A double-faced structure that produces equal numbers of each type of stitch on both needle beds, symmetrically displayed on both fabric surfaces, and typically in the same sequence. Because balanced fabrics have uniform tension and stitch type on both sides of the fabric, they generally do not curl at their edges.

Face & Reverse on the Same Side Surface: Typically made with purl weft knitting, using double-headed needles. It can establish one face stitch (with one hook) and one reverse stitch (with the other hook) per needle. As a result, the machine is able to perform both types of stitches on the same surface of fabric such that the points (intermeshing point 3 and 4) are not necessarily identical to each other as well as earlier intermeshing points (1 and 2). This method provides an opportunity to add flexibility regarding the behavior and appearance of the textile.

Draw-off of Fabric: In knitting, the fabric always draws off the needles on the side opposite from that of their hooks. When two groups of needles are used, with a vertical or at an angle arrangement to each other, the hooks of one group face away from the other. Fabric is created in the space between these two needle sets and pulled off from here. This configuration allows for seamless production and even draw-off of the fabric.

References

Subscribe to my newsletter

Read articles from Arshin shaikh directly inside your inbox. Subscribe to the newsletter, and don't miss out.

Written by

Arshin shaikh

Arshin shaikh

Hi! I'm Arshin, a textile science enthusiast and designer with a passion for making fashion both creative and sustainable. I love exploring different aspects of textiles, from knitting to innovative materials, and sharing my knowledge through simple and engaging articles. My goal is to help others understand the fascinating world of textiles and how we can create clothing that's not only beautiful but also kind to our planet. Whether you're a student, a fellow designer, or just curious about how fabrics are made, I hope my blog makes these topics fun and easy to learn about. Join me as I explore everything from knitting techniques to future trends in textile science!