How Pneumatic Caulking Tools Evolve to Improve Ergonomics

Shreya Sulkunde

Shreya Sulkunde

Unpacking the Shift: From Overwhelming Fatigue to Ergonomic Innovation

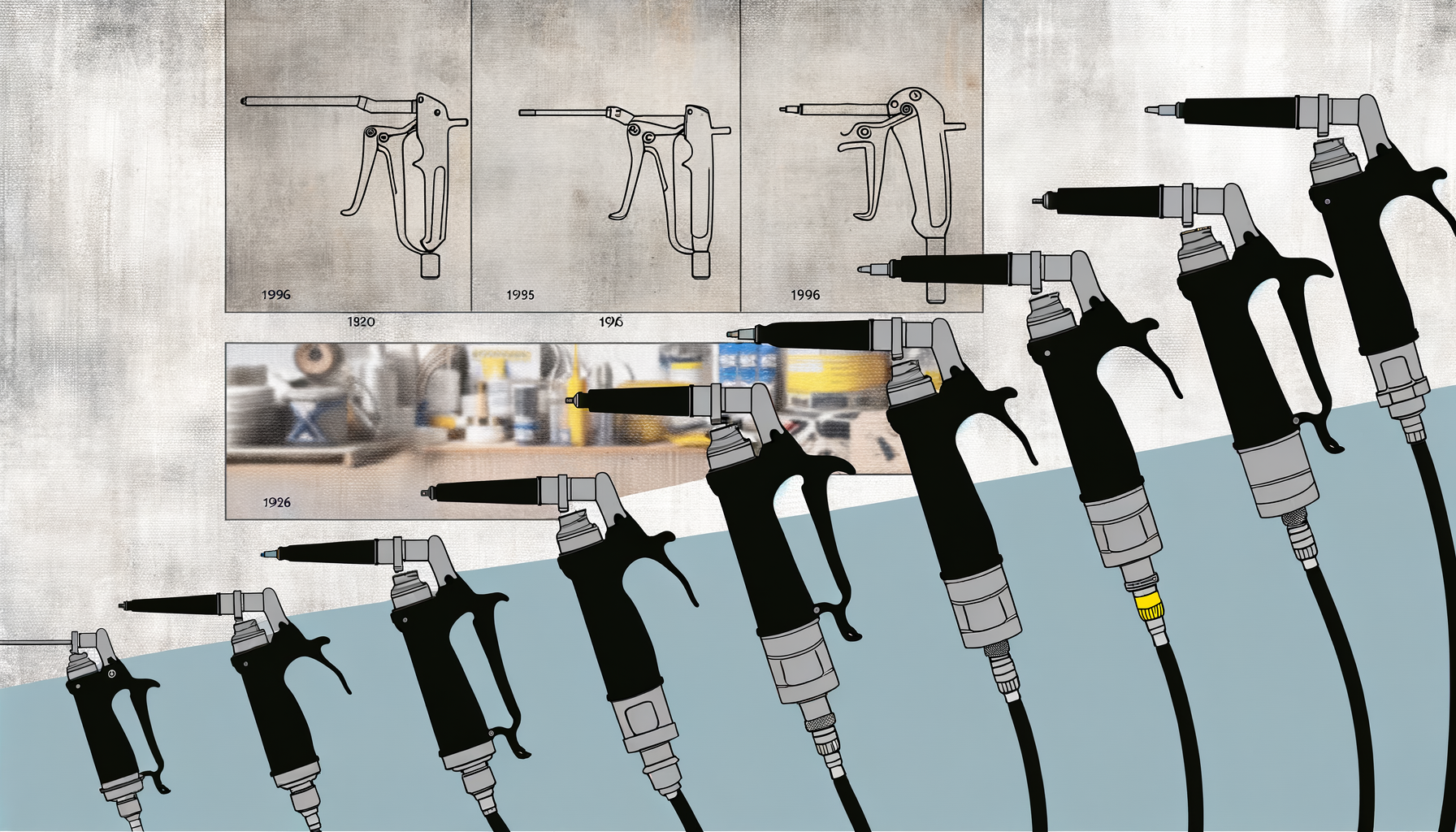

In the world of construction, meticulous precision and efficiency are paramount. No task more so than caulking—a seemingly straightforward yet challenging job requiring skillful application for leak-proof seals. Over the years, the rise of pneumatic caulking tools has been a revelation, replacing manual fatigue with unparalleled ease and efficiency.

However, this evolution doesn't stop here. Technological advancements are relentlessly pushing the boundaries, with a pronounced emphasis on improved ergonomic designs. This evolution is shaping how professionals execute day-to-day tasks by minimizing operator fatigue and maximizing efficiency.

The Mounting Challenges in Conventional Tools

Before diving into innovations, it's essential to understand the constraints of traditional caulking tools. Painstakingly demanding, these manually operated devices often pave the way for wrist strain and prolonged fatigue. Operators face hours of intense labor in uncomfortable positions, sacrificing comfort and health in the quest for customer satisfaction.

Embracing Pneumatic Advancements: A New Era

With technological leaps, pneumatic caulking tools have reimagined ergonomic applications in unparalleled ways. Let's explore these technological advancements reshaping the industry:

1. Weight Reduction and Balanced Designs

Pneumatic tools historically carried a burdensome weight, making prolonged use problematic. However, modern advancements with composite materials have significantly reduced the weight—ushering in an era of less strain for operators. These tools now boast a balanced weight distribution translating to smoother handling and ease of use.

2. Improving the Grip and Handle Design

Innovations in handle design have made a world of difference. Ergonomically molded grips provide excellent fit and comfort, facilitating better control and maneuverability during high-precision jobs. By reducing slippage and promoting a relaxed grip, these designs alleviate stress on muscles over long hours.

3. Customized Trigger Sensitivity

Operator comfort takes center stage with breakthrough variable trigger sensitivity technologies. These innovative triggers allow users to customize the tool's response, enhancing comfort and handling, which is crucial during delicate applications.

4. Noise and Vibration Dampening

Pneumatic tools are often criticized for their noise and vibration levels. Recent advancements have focused on minimizing these concerns. Enhanced noise-dampening technologies and vibration isolation techniques have paved the way for quieter operations and reduced operator fatigue, ensuring a more pleasant work atmosphere.

5. Incorporating User Feedback

A significant driver in development is direct user feedback. Manufacturers prioritize understanding the needs and challenges faced by frontrunners, enabling tailor-made ergonomic solutions that resonate with real-world scenarios.

Pioneering Innovations Reshaping the Industry

Global manufacturers are at the forefront of integrating these technologies into their pneumatic caulking tools. The emphasis is on creating tools that resonate with operators on all levels—emotionally and physically. Companies generating innovative designs strengthen their brand equity and build trust within the construction community.

a. Makita's Smart Ergonomics

Renowned for its power tools, Makita has leaped forward with its state-of-the-art ergonomic caulking tools. Their unique approach leverages smart materials and designs that foster user adaptability and ease.

b. DeWalt's User-Centric Approach

DeWalt's user-centric designs take into account nuanced insights into worker ergonomics. Their tools prioritize user comfort and reduce stress-inducing factors during high-intensity caulking.

The Road Ahead: Embracing Change and Progress

The construction industry stands at the edge of a transformation fueled by unprecedented technological advancements. For professionals, choosing the right pneumatic solutions can create a healthier, more productive workforce.

Nevertheless, the onus remains with manufacturers to continually push the envelope in ergonomic innovations, ensuring sustainable practices and user-centric designs. These technological advancements may very well unlock new realms of efficiency and empowerment for practitioners worldwide.

Diversifying beyond the present, envision a future where pneumatic caulking tools continue to evolve—ushering in a transformative wave that embraces operator wellness, efficiency, and success in equal measure.

Explore Comprehensive Market Analysis of Pneumatic Caulking Tools Market

Source -@360iResearch

Subscribe to my newsletter

Read articles from Shreya Sulkunde directly inside your inbox. Subscribe to the newsletter, and don't miss out.

Written by