How KIGLAND Scaled Custom Anime Mask Production with Open-Source Tools

Lucy Zhang

Lucy Zhang

Originally published at How KIGLAND Scaled Custom Anime Mask Production with Open-Source Tools - NocoBase.

Introduction

In Suzhou China, a team is quietly reinventing the world of personalized production. They don’t make fast-fashion goods or chase mass production, but they've built a loyal global following among cosplay fans.

Meet KIGLAND — a studio that crafts 2D-style character head masks, known as KIGURUMI. These masks are highly personalized, tricky to customize, and require precise handiwork — the perfect example of low-volume, high-variety manufacturing.

At first glance, they might seem like a niche artisan team.

But in reality, they’re more like a flexible manufacturing lab for entertainment products. By combining digital production, standardized workflows, and AI-driven supply chain innovation, they’re transforming handcrafted creations into near-industrial products.

From GitHub Issues to Lark's Base

In its early days, KIGLAND ran things like a true hacker-style startup:

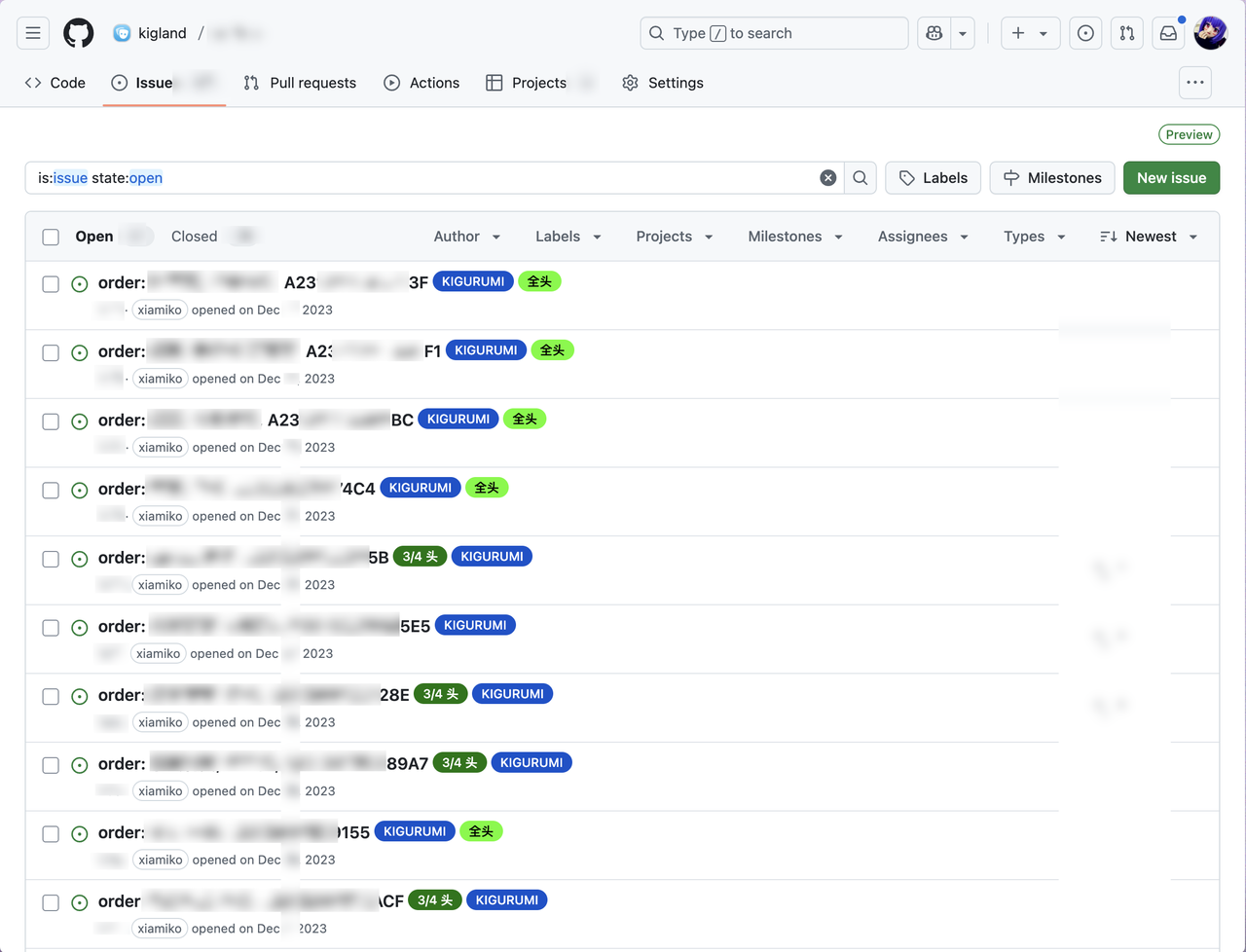

Customer orders were tracked in GitHub Issues

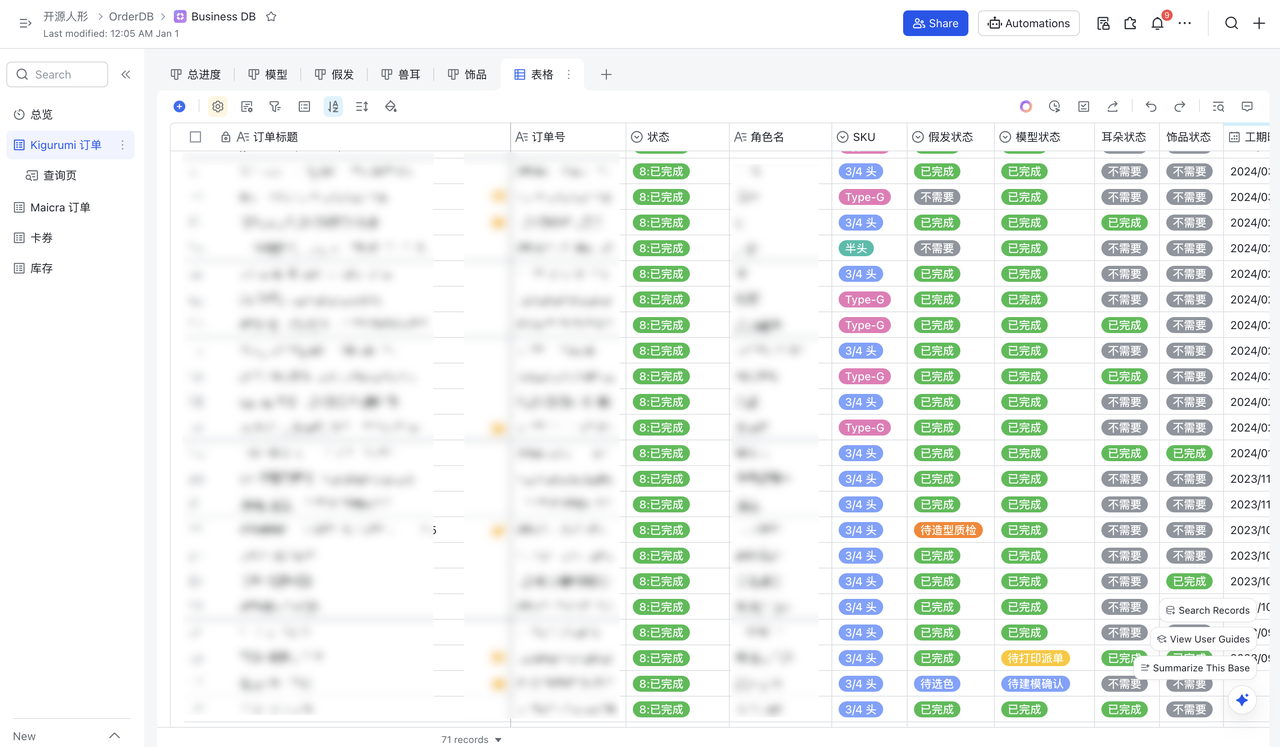

Production progress was updated in Lark's Base

Feedback and communication were scattered across comments, screenshots, and chat threads

Early use of GitHub Issues to manage orders:

Manage orders through Lark's Base:

“It was manageable when we were small—but as soon as the volume picked up, the whole system started to break down.”

The problems will sound familiar to anyone who’s scaled from side project to real operation:

Limited structure – Traditional Issue lists couldn’t handle the growing number of custom fields or stage-specific data needs across departments.

Workflow blind spots – Comments and discussions weren’t easily searchable or structured, making it hard to track progress.

Collaboration breakdown – Non-technical team members struggled with GitHub’s developer-oriented tools, and the spreadsheet setup required increasingly complex permission management.

As the communication overhead grew exponentially, KIGLAND knew it was time to stop patching things together—and start looking for a real system built for their unique needs.

Looking for a System They Could Truly Own

As open-source veterans with strong technical backgrounds, KIGLAND’s founding team wasn’t looking for yet another bloated SaaS platform. They needed something different—something they could shape around their business, not the other way around.

“We wanted a tool that could grow with us—not a rigid platform we had to constantly work around.”

So they started exploring alternatives to traditional tools like Airtable. After testing several options, they landed on NocoBase.

The reasons were clear:

Flexible data modeling to handle the complexity of custom orders

Plugin-based architecture with open APIs, giving their team the freedom to extend functionality

User-friendly interface with a shallow learning curve, even for non-developers

A fast-moving, active open-source community

And above all: self-hostable and fully open, giving them complete control over their system

A Custom Management System—Built in Just Three Weeks

In less than three weeks, KIGLAND had a fully functional internal management system built entirely on NocoBase. It was designed to match their workflows exactly, without compromise.

Their setup included:

End-to-end order lifecycle management – covering every step from order intake, design, and production, to quality control and shipping

Multi-role collaboration – with clearly defined permissions for sales, design, and production teams, ensuring smooth handoffs and accountability

Log-driven responsibility tracking – enabling full traceability and faster issue resolution

Flexible materials and inventory tracking – with custom categories, linked records, and real-time visibility

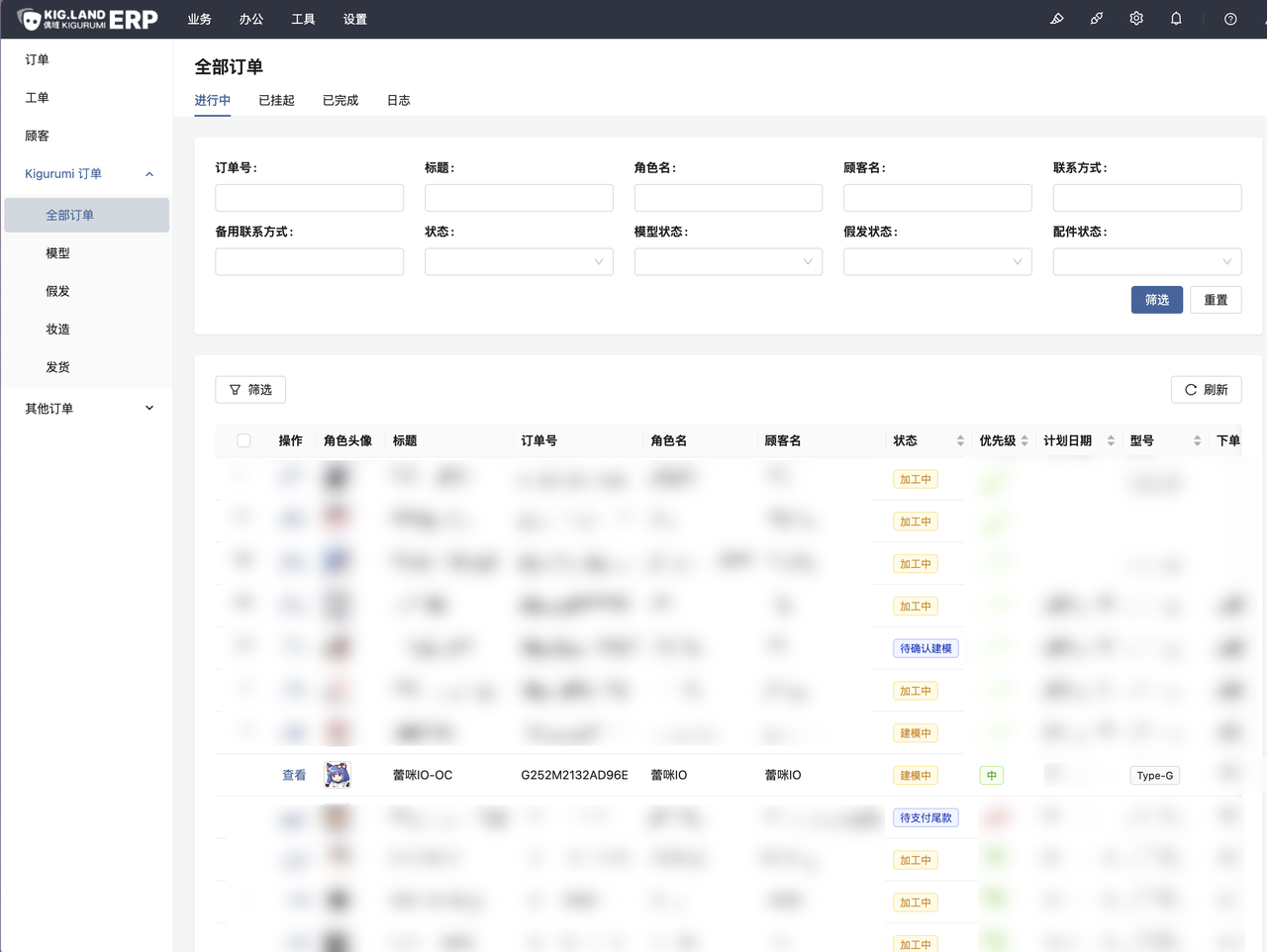

Order list managed in NocoBase:

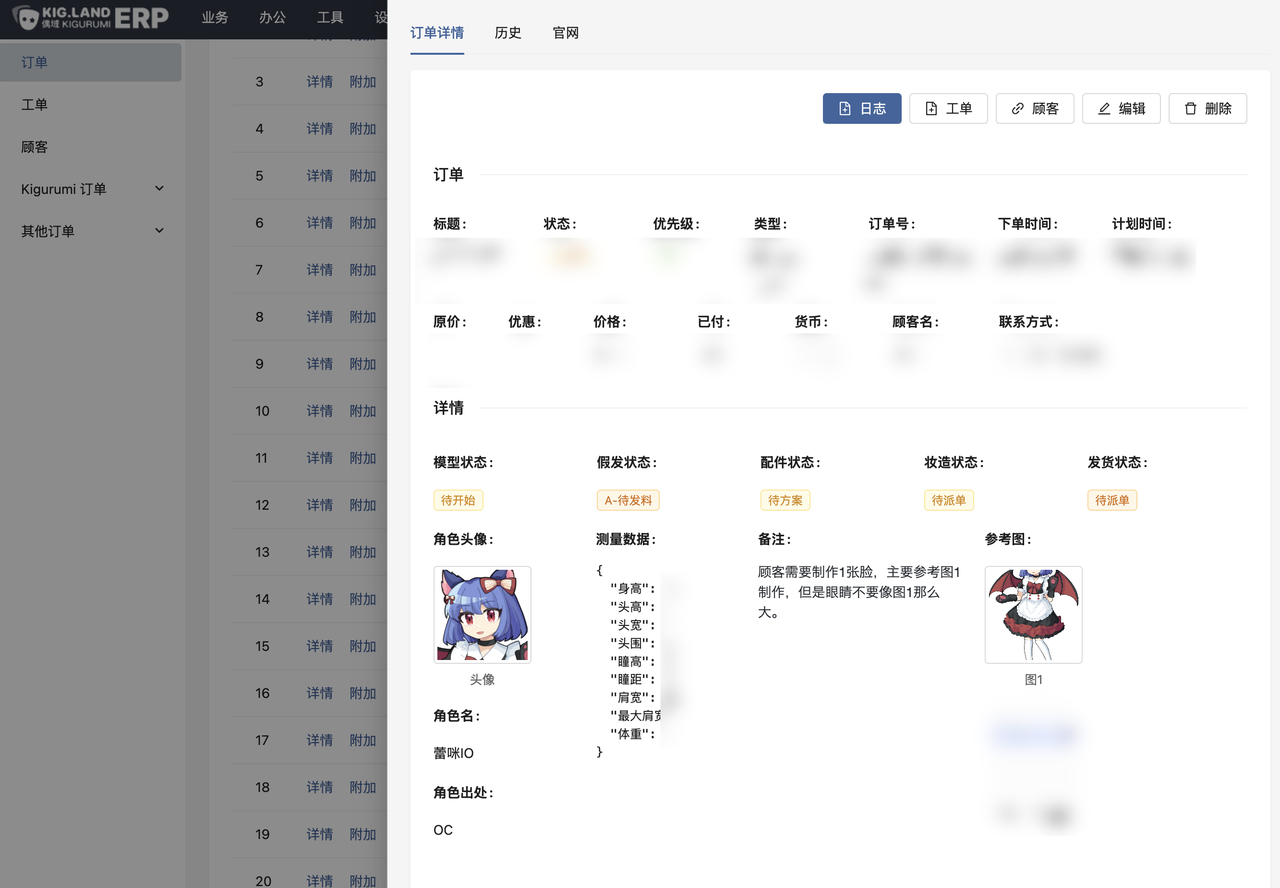

Order details and production steps:

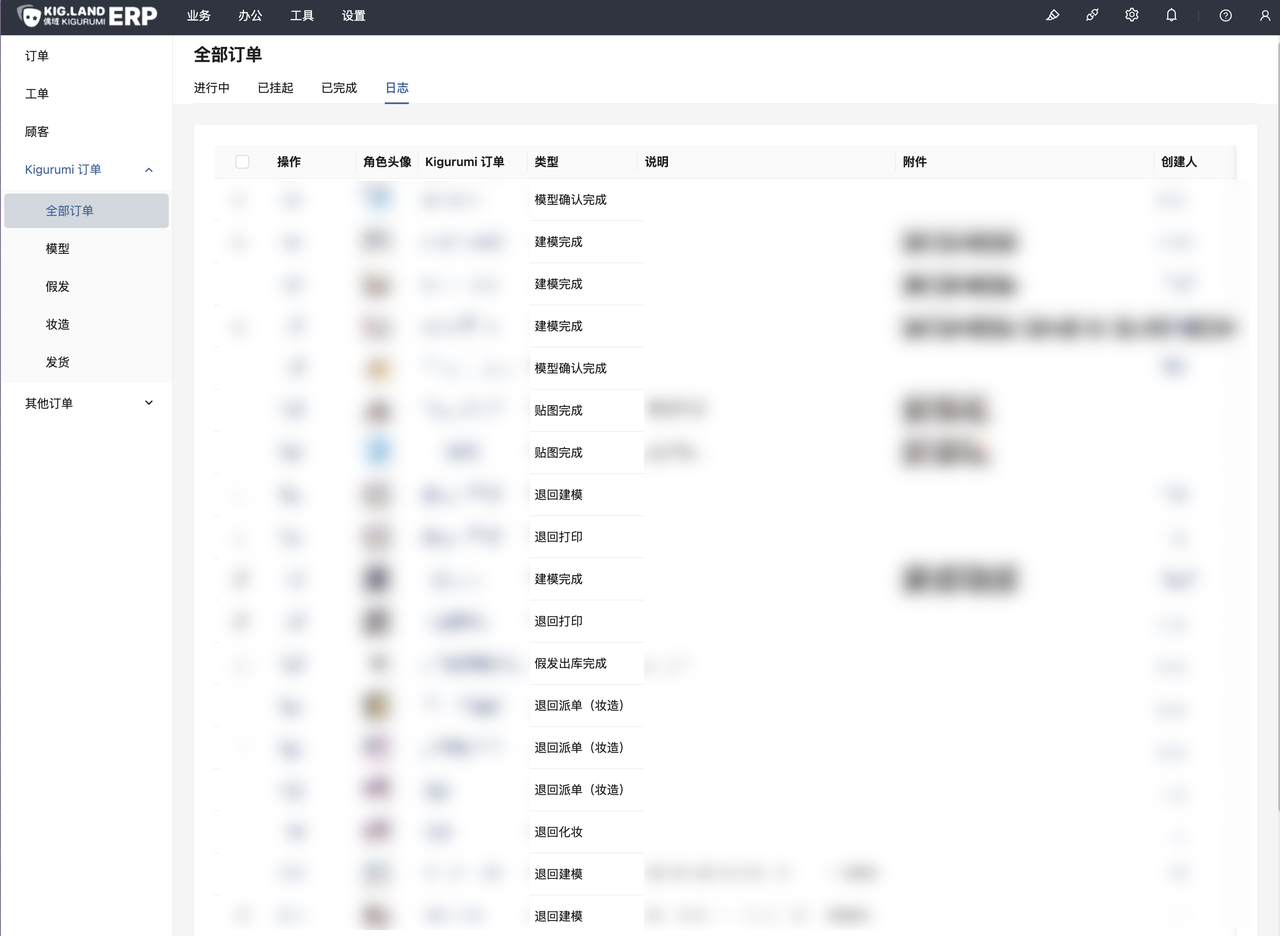

Activity logs and traceability:

Linking logs to specific orders:

Once the core system was up and running, the team continued to evolve it alongside NocoBase’s regular updates—adapting new features as they came and contributing feedback to the community.

Three Quarters In, the Results Spoke for Themselves

“After adopting NocoBase, we went from a scrambling small studio to one of the top teams in our niche.”

And the numbers back it up:

📦 3× increase in order processing capacity

❌ 80% drop in collaboration-related errors

😊 Significantly higher customer satisfaction

🔧 Greater self-sufficiency for the tech team, with ongoing in-house development and iteration

But the biggest win? The team finally stepped out of the day-to-day grind and began focusing on growing the business and improving user experience.

Here’s what their customers had to say:

Scaling Beyond the System

With NocoBase as their foundation, KIGLAND continues to expand what their internal systems can do—one step closer to building a fully automated, fully customized production pipeline.

Their roadmap includes:

AI-powered production scheduling using self-hosted LLMs and a modular control platform (MCP)

Predictive manufacturing models based on historical order data, enabling real-time dispatch to suppliers

Client-side ordering integration for a fully standardized, end-to-end custom workflow

For KIGLAND, this isn’t just about adopting better tools—it’s a strategic shift in how they scale.

“In personalized manufacturing, systemization is no longer a ‘nice to have.’ It’s the foundation for growth.” —Remi, Co-Founder of KIGLAND

Final Thoughts

KIGLAND’s journey is a reminder of a simple but powerful truth:

The more complex and personalized your business becomes, the more structure you need underneath. And if you want to scale, you can’t rely on manual processes alone.

Their transformation wasn’t powered by an out-of-the-box solution—it was made possible by a system they could shape, extend, and evolve alongside their business.

For teams navigating digital transformation, the real breakthrough might not come from finding a perfect all-in-one platform—but from building on something like NocoBase: a flexible, open foundation that grows with you.

Subscribe to my newsletter

Read articles from Lucy Zhang directly inside your inbox. Subscribe to the newsletter, and don't miss out.

Written by