Data Doesn’t Lie: 7 Reasons It’s a Game-Changer for Manufacturing

Sarah R. Weiss

Sarah R. Weiss

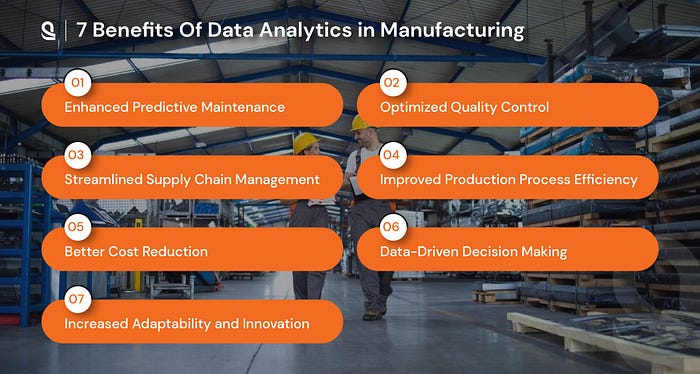

In today’s fast-paced world, manufacturers that embrace data analytics don’t just survive — they lead. From predicting machine failures to driving innovation, here’s how data is revolutionizing the manufacturing landscape.

1. Predict Problems Before They Happen: Enhanced Predictive Maintenance

Why wait for machines to break down when you can stop issues before they start? With predictive maintenance powered by data analytics, manufacturers can:

Identify equipment issues early using real-time sensor data and machine learning.

Reduce downtime and disruptions by planning proactive maintenance.

Extend machine life and save big on emergency repairs.

Bottom Line: Fewer breakdowns, more productivity, and longer-lasting equipment.

2. Quality That Speaks for Itself: Optimized Quality Control

Consistent product quality is no accident — it’s driven by data. With analytics, manufacturers can:

Catch defects in real-time using AI-powered vision systems and statistical controls.

Minimize material waste by detecting issues early in the production process.

Strengthen brand reputation by delivering flawless, high-quality products.

Bottom Line: Better products, fewer returns, and happier customers.

3. Run Lean, Stay Agile: Smarter Supply Chain Management

A responsive, data-driven supply chain keeps production smooth and efficient. With analytics, manufacturers can:

Forecast demand more accurately and avoid overstock or shortages.

Track inventory and shipments in real-time to reduce delays.

Improve supply chain visibility and respond quickly to market shifts.

Bottom Line: Lower storage costs, better planning, and faster delivery.

4. Speed Up Without Sacrificing Quality: Efficient Production Processes

Data Analytics in Manufacturing

Want faster, smarter workflows? Data helps manufacturers:

Spot bottlenecks and inefficiencies in real-time.

Streamline operations by making informed process improvements.

Reduce resource waste while increasing throughput.

Bottom Line: Higher output, lower costs, and smarter use of time and materials.

5. Cut Costs Without Cutting Corners: Data-Driven Cost Reduction

Analytics empowers manufacturers to run lean operations. Here’s how:

Optimize energy and material usage with smart, data-backed planning.

Minimize waste and scrap by aligning output with demand.

Automate repetitive tasks to reduce labor costs and boost productivity.

Bottom Line: Lower operating costs and a better return on investment.

Subscribe to my newsletter

Read articles from Sarah R. Weiss directly inside your inbox. Subscribe to the newsletter, and don't miss out.

Written by

Sarah R. Weiss

Sarah R. Weiss

I share insights on Software Development, Data Science, and Machine Learning services. Let's explore technology together!