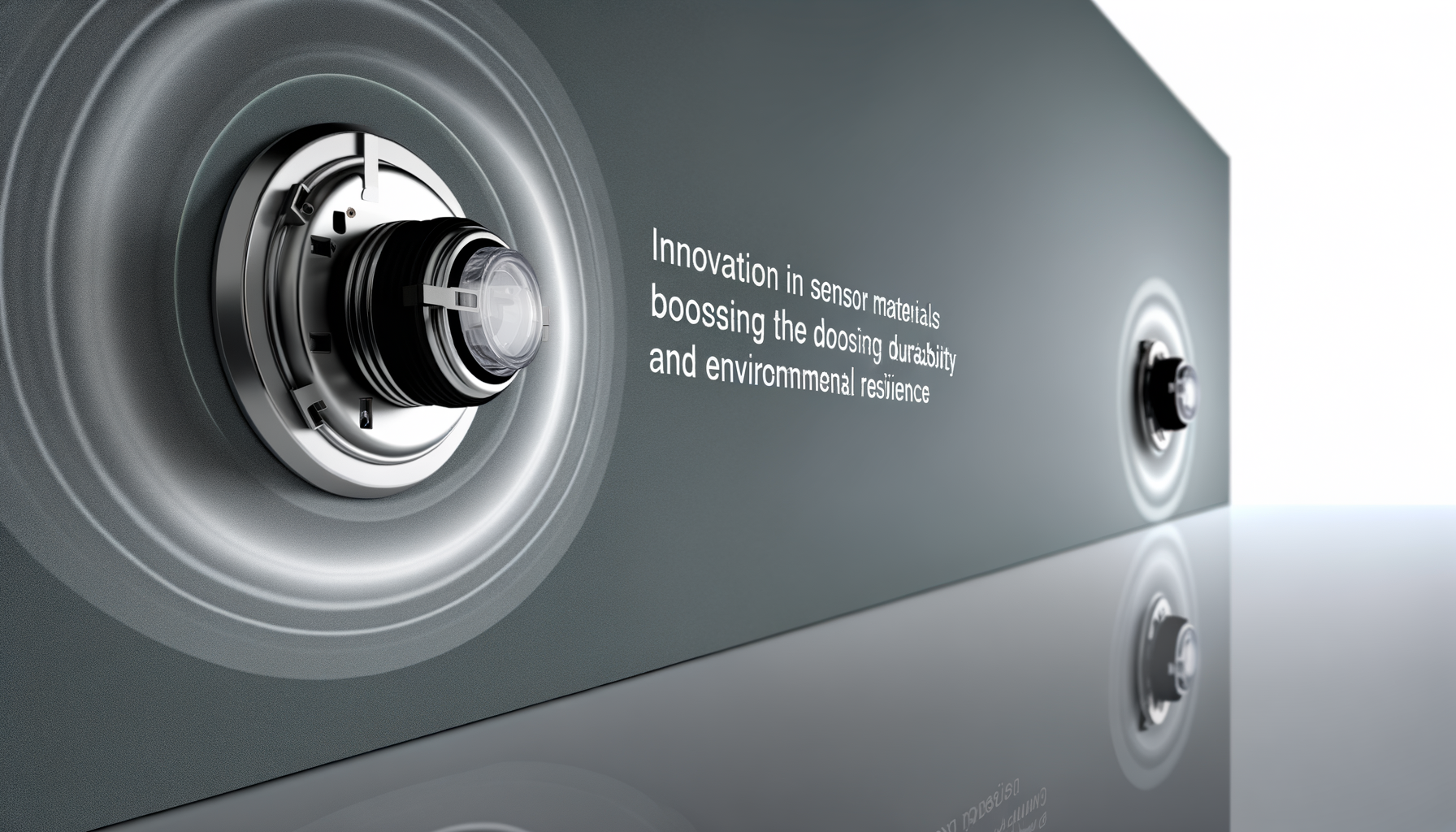

How Innovations in Sensor Materials Boost Durability and Environmental Resilience of Wall Mount Occupancy Sensors

Shraddha Shinde | 360iResearch™

Shraddha Shinde | 360iResearch™

In today's rapidly evolving world, the demand for smart and efficient building automation technologies is higher than ever before. Among these, wall mount occupancy sensors play a pivotal role in enhancing energy efficiency, improving comfort, and ensuring safety within various environments-from residential spaces to commercial offices and industrial facilities. As these sensors become increasingly integrated into modern infrastructures, the materials that constitute them are undergoing significant advancements to boost their durability and environmental resilience.

Understanding Wall Mount Occupancy Sensors

Wall mount occupancy sensors are devices mounted on walls, designed to detect the presence or absence of occupants in a room or space. They trigger specific actions such as turning lights on or off, adjusting HVAC systems, or alerting security protocols based on occupancy patterns. Traditionally, these sensors have relied on technologies like passive infrared (PIR), ultrasonic, or dual-technology sensing to recognize human presence.

However, beyond their sensing capabilities, the physical composition of these sensors-particularly the materials used in their sensors, housings, and mounting components-plays a critical role in their overall performance, reliability, and longevity.

Challenges Faced by Occupancy Sensors

Occupancy sensors are often installed in environments exposed to various stress factors, including:

Temperature fluctuations: Extreme heat or cold can degrade sensor components.

Humidity and moisture: Moisture ingress can cause corrosion or short circuits.

Dust and particles: Accumulated dirt can interfere with sensor optics or electronics.

Mechanical impacts: Physical knocks or vibrations may damage sensitive parts.

Chemical exposure: Cleaning agents and pollutants can erode materials.

Given these challenges, the materials chosen for sensor components must withstand such conditions to maintain functionality over extended periods.

Advancements in Sensor Materials

Recent innovations in material science and engineering have introduced new solutions that significantly improve the durability and environmental resistance of wall mount occupancy sensors. These advancements include:

1. High-Performance Polymers and Composites

Modern sensors often utilize advanced polymers such as polycarbonate (PC), acrylonitrile butadiene styrene (ABS), and polyethylene terephthalate (PET) composites for housings. These materials exhibit superior impact resistance, UV stability, and temperature tolerance, making sensors less prone to cracking, yellowing, or warping.

Moreover, the incorporation of nanomaterials and fiber reinforcements into these polymers enhances mechanical strength and thermal stability without adding excessive weight.

2. Coatings for Environmental Protection

Protective coatings have evolved beyond simple paints or sealants. Nanocoatings and hydrophobic layers are now applied to sensor surfaces to repel water, dust, and oils. These coatings minimize sensor contamination and simplify maintenance.

For outdoor or harsh indoor environments, anti-corrosion treatments protect metallic components from oxidization. Additionally, UV-resistant coatings prolong the life of plastic components exposed to sunlight.

3. Robust Sensor Elements

The sensitive elements inside occupancy sensors have also benefitted from material advancements. For example, PIR sensor lenses are increasingly manufactured from crystalline materials with enhanced optical clarity and scratch resistance.

In ultrasonic sensors, piezoelectric components utilize new ceramic materials that maintain performance under wider temperature ranges and are less sensitive to mechanical fatigue.

4. Advanced Gasket and Seal Materials

Ensuring that moisture and dust cannot penetrate the sensor's interior is critical for long-term reliability. Modern wall mount occupancy sensors now employ fluorosilicone and fluorocarbon elastomers for gaskets and seals. These materials provide excellent chemical resistance and elasticity over a broad temperature spectrum, ensuring tight seals that endure.

5. Sustainable and Eco-friendly Materials

Alongside durability, sustainability is gaining importance. Sensor manufacturers are exploring biodegradable and recyclable polymers, as well as materials sourced from renewable resources, to reduce environmental impact without compromising sensor resilience.

Impact of Material Advancements on Sensor Performance

These material enhancements translate to tangible benefits:

Extended Service Life: Sensors can function reliably for years, minimizing replacements and lowering total cost of ownership.

Lower Maintenance Costs: Durable materials resist damage and contamination, reducing cleaning and repair needs.

Improved Accuracy: Clean, intact optical components and sensor elements ensure consistent occupancy detection.

Broader Application Range: Enhanced resilience allows sensors to be deployed in more challenging or extreme environments.

Energy Efficiency Gains: Reliable sensors maintain optimal operation of lighting and HVAC systems, contributing to energy savings.

Case Studies and Industry Examples

Leading sensor manufacturers have integrated these material innovations into their latest product lines. For instance, a recent model from a top brand uses a polycarbonate-ABS composite with a nanocoating finish, enabling the sensor to withstand high humidity levels in tropical climates without signal degradation.

Another example is the introduction of PIR sensors featuring sapphire-based lenses, which resist scratching and provide superior infrared transmission, ensuring accurate motion detection even in dusty or smoky conditions.

The Future of Wall Mount Occupancy Sensor Materials

Material science continues to evolve, with research focused on:

Self-healing materials that can repair minor scratches or cracks autonomously.

Smart materials capable of changing properties (like transparency or conductivity) in response to environmental stimuli.

Enhanced biodegradable composites offering both durability and environmental sustainability.

Integrated antibiofouling materials to minimize microbial growth on sensor surfaces.

Such innovations promise to further enhance the reliability, lifespan, and ecological footprint of occupancy sensors.

Conclusion

Advancements in sensor materials are revolutionizing the durability and environmental resilience of wall mount occupancy sensors. By embracing cutting-edge polymers, protective coatings, robust sensor elements, and superior sealing materials, manufacturers are delivering products that withstand the rigors of real-world environments while maintaining high performance.

For facility managers, building designers, and technology integrators, understanding these material advancements is crucial in selecting occupation sensors that offer long-term reliability, reduce maintenance burdens, and support sustainable building operations.

As the market for smart building technologies expands, investing in sensors built with these modern materials ensures both operational excellence and future-ready infrastructure.

Explore Comprehensive Market Analysis of Wall Mount Occupancy Sensors Market

SOURCE -- @360iResearch

Subscribe to my newsletter

Read articles from Shraddha Shinde | 360iResearch™ directly inside your inbox. Subscribe to the newsletter, and don't miss out.

Written by