Digital Twins: Bridging the Physical and Digital Worlds

Sharmila Korada

Sharmila Korada

“If you can’t measure it, you can’t improve it.” — Peter Drucker

Imagine if engineers could go beyond mere measurement. What if they could simulate, predict, and optimize a system—whether it's a jet engine, a hospital, or an entire city—before it breaks down or is even built? This is the promise of Digital Twins, a rapidly advancing technology that allows businesses and researchers to create virtual replicas of real-world entities and interact with them in real time. As digitization drives industry transformation, digital twins become the crucial link between physical operations and digital insights.

What Are Digital Twins?

A Digital Twin is not just a 3D model—it’s a smart, data-driven virtual counterpart of a real-world object, process, or system. It is continuously updated with data from sensors and devices in the real world. This digital replica behaves just like its physical counterpart and can simulate its performance, respond to changes, and even forecast future outcomes. For instance, a digital twin of a car engine receives data from sensors embedded in the actual engine and uses that data to reflect performance, identify problems, and suggest maintenance strategies—all in real time. It turns passive monitoring into proactive intelligence.

The process of Digital Twining generates a digitalized counterpart of a real instrument or site by means of sensors. Hence it is well possible to create the digital twin of any asset even before the asset has been physically created. In the process of creating a digital twin for any physical asset, engineers gather data from and synthesize them into all sources of information available from physical data, manufacturing data, operational data, and insights from analytics software. This set of information along with artificial intelligence algorithms is fed into a physics-based virtual model, and analytics are applied to these models to generate useful insights about the physical asset. Continuous data flow helps analyze and get the best possible insights relating to business-scale assets, which in turn optimizes the business outcome. Thus, the digital twin acts as a live model of the physical equipment.

Anatomy of a Digital Twin

Understanding the building blocks of a digital twin helps clarify its value:

Physical Object: This could be anything—a turbine, an assembly line, or even a human heart. It’s the real-world entity that’s being mirrored digitally.

Digital Model: This is a high-fidelity representation of the physical object. It doesn’t just look like the real thing; it behaves like it too. The model is often built using engineering simulations, CAD data, or machine learning models.

Data Connection: Through the Internet of Things (IoT), data from the physical object flows into the digital model in real time. Sensors measure temperature, vibration, speed, usage—whatever’s relevant—and send it to the twin.

Intelligence Layer: This includes analytics, AI algorithms, and machine learning models that make sense of the incoming data. It allows the digital twin to simulate various scenarios, detect anomalies, predict failures, and recommend optimizations.

Together, these components form an intelligent feedback loop that brings new levels of insight and control.

Where Are Digital Twins Making an Impact?

Digital twins aren’t limited to one industry. They’re proving valuable across many sectors, each with specific use cases that drive real-world results.

1. Manufacturing

The manufacturing industry is about to undergo a transformation thanks to digital twins. The design, manufacture, and maintenance of products are significantly impacted by digital twins. It decreases throughput times while optimizing and increasing manufacturing efficiency.

Manufacturers are early adopters of digital twin technology. They use it to:

Predict Equipment Failures: By analyzing vibration and temperature data, a digital twin can foresee equipment malfunctions before they happen.

Simulate Factory Workflows: Engineers can virtually reconfigure production lines to find the most efficient layout—without stopping actual operations.

Reduce Waste: Simulations help spot inefficiencies and reduce defective output, saving money and raw materials.

Digital twins turn traditional factories into smart factories by enabling real-time insights and agile responses to change.

2. Smart Cities

The planning and execution of smart cities using digital twins and Internet of Things data contributes to improved economic growth, effective resource management, a smaller environmental impact, and an overall improvement in the standard of living for citizens. By gathering information from multiple sensor networks and intelligent systems, the digital twin model can assist policymakers and city planners in the planning of smart cities. They are also able to make well-informed decisions about the future thanks to the data from the digital twins.

City planners and municipalities use digital twins to design, simulate, and optimize urban infrastructure:

Traffic Management: Simulate and optimize traffic flows to reduce congestion and pollution.

Disaster Response: Model how a flood or fire would impact different neighborhoods, helping first responders prepare.

Resource Allocation: Track energy, water, and waste usage in real time to improve sustainability efforts.

For example, Singapore's “Virtual Singapore” project is a city-scale digital twin that simulates everything from pedestrian flow to pollution levels.

3. Healthcare

In the healthcare industry, digital twins and IoT data can be extremely useful for patient monitoring, preventative maintenance, cost reduction, and individualized treatment.

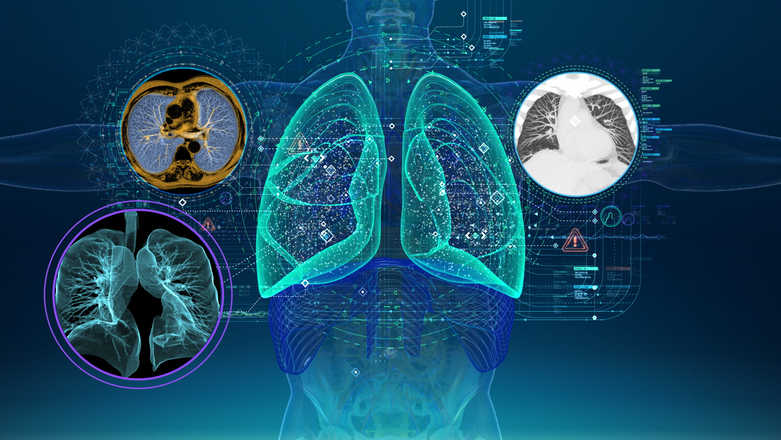

In healthcare, digital twins are ushering in an era of precision medicine:

Patient-Specific Models: Create virtual models of patients to simulate treatment options and personalize therapies.

Organ Replicas: Develop digital hearts, lungs, or kidneys to test the effects of drugs or surgeries before applying them in real life.

Hospital Management: Use twins of healthcare facilities to optimize staff scheduling, equipment usage, and patient flow.

This approach doesn’t just treat symptoms—it anticipates and prevents illness.

4. Aerospace & Automotive

Digital Twins can be used in the automobile sector for creating the virtual model of a connected vehicle. It captures the behavioral and operational data of the vehicle and helps in analyzing the overall vehicle performance as well as the connected features. It also helps in delivering a truly personalized/ customized service for the customers.

In aerospace and automotive industries, safety and performance are everything:

Flight Simulation: Digital twins of aircraft can test performance under different conditions—without leaving the ground.

Vehicle Maintenance: Automakers use twins to track wear and tear across a vehicle’s lifecycle and alert users to potential failures.

Design Iteration: Engineers iterate faster by testing prototypes digitally, reducing time and cost in the development process.

Rolls-Royce, for instance, uses digital twins for engine health monitoring, resulting in more efficient service schedules and fewer in-flight incidents.

5. Energy

Energy companies deploy digital twins to make power generation cleaner and more reliable:

Smart Grids: Monitor demand and supply across electricity networks and simulate peak usage scenarios.

Wind and Solar Farms: Track performance of turbines or panels in real-time and predict maintenance needs.

Oil & Gas Platforms: Simulate hazardous scenarios to improve safety and minimize environmental impact.

By modeling the entire system, companies can reduce energy waste and improve resilience.

Technologies Behind Digital Twins

Digital twins sit at the intersection of several advanced technologies:

IoT Sensors: These are the eyes and ears on the ground. They collect data from machines, infrastructure, or human bodies and send it to the digital twin.

Cloud Computing: Provides the computational power and storage needed to process massive data streams in real time.

Edge Computing: Handles time-sensitive data close to the source—especially useful in remote areas or mission-critical systems.

AI & Machine Learning: Drive predictive capabilities, optimize system behavior, and identify patterns that humans might miss.

AR/VR Interfaces: Enable engineers, doctors, or operators to interact with the twin in immersive ways.

5G Connectivity: Ensures rapid, low-latency data transmission to keep twins synchronized with their real-world counterparts.

All these technologies converge to make digital twins not just possible—but powerful.

Why Digital Twins Matter

The advantages of digital twins extend beyond simple monitoring:

Proactive Maintenance: Instead of waiting for something to fail, a digital twin warns you beforehand.

Operational Efficiency: See where bottlenecks are happening in real time and adjust accordingly.

Design Innovation: Test hundreds of design variations in a risk-free environment.

Safety & Risk Reduction: Simulate hazardous scenarios before they become real threats.

Sustainability: Reduce energy waste, emissions, and environmental impact with smarter resource use.

They empower teams to act with foresight, not just hindsight.

Challenges Ahead

Despite the promise, digital twins face several challenges:

Data Privacy & Security: Sensitive data (especially in healthcare or critical infrastructure) needs to be protected from cyber threats.

System Integration: Not all legacy systems are ready to work with digital twins. Integration can be complex and time-consuming.

Data Management: More sensors mean more data. Filtering what’s relevant becomes a challenge.

High Costs: Developing high-fidelity digital twins and the infrastructure to support them requires significant investment—though costs are dropping with time.

These barriers are real but surmountable with the right planning and strategy.

The Road Ahead

Digital twins are evolving rapidly. With advances in generative AI, blockchain for data integrity, and even quantum computing for simulation, we’ll soon see:

Autonomous twins that adapt and make decisions without human intervention.

Massive twin ecosystems where entire factories, hospitals, or cities are simulated collaboratively.

Integration with the metaverse, where real and virtual worlds merge for training, operations, or design.

Tomorrow’s digital twins won’t just mimic reality—they’ll improve it in real time.

It is unequivocally the next way for data scientists or data analysts to create a simplified and easy way for end users to experience this information.

Final Thoughts

Digital twins are a foundational technology in the age of Industry 4.0, smart cities, and precision medicine. Whether you’re optimizing supply chains, diagnosing disease, or planning a city’s future, the ability to model reality digitally gives you a superpower: insight before action.

Digital twins are revolutionizing the way industries operate by providing a bridge between the physical and digital worlds. They offer unprecedented insights and control, enabling proactive maintenance, operational efficiency, and design innovation. As they continue to evolve, digital twins will become even more integral to sectors like manufacturing, healthcare, smart cities, aerospace, and energy. Despite challenges such as data privacy and integration, the potential benefits are immense. By harnessing the power of digital twins, businesses and researchers can anticipate and adapt to changes, ultimately leading to smarter, more sustainable, and resilient systems. As we look to the future, digital twins will not only mimic reality but enhance it, driving forward the next wave of technological and strategic advancements.

They represent not just a technological leap—but a strategic shift toward predictive, adaptive, and intelligent systems.

Subscribe to my newsletter

Read articles from Sharmila Korada directly inside your inbox. Subscribe to the newsletter, and don't miss out.

Written by

Sharmila Korada

Sharmila Korada

I'm a Software Development Engineer with a passion for backend development, AI/ML, and building scalable cloud solutions. I enjoy applying my skills in Python, AWS, and FastAPI to solve real-world challenges. I believe learning is most powerful when shared — which is why I use this space to document my journey, share insights, and grow with the community. For me, "sharing knowledge leads to gaining knowledge."