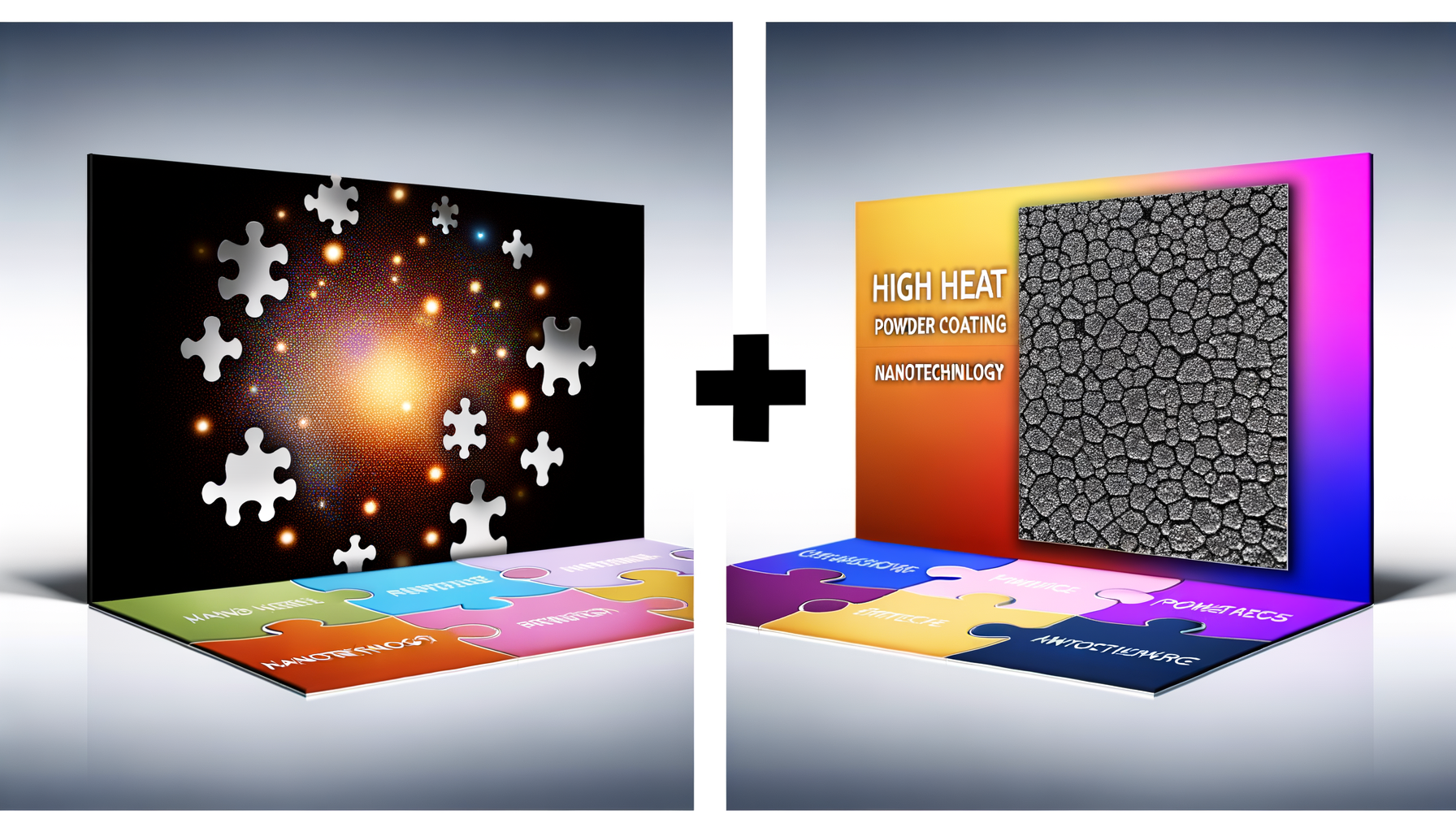

Integration of Nanotechnology Enhances Thermal Resistance and Durability of High Heat Powder Coatings

Pranali Baderao

Pranali Baderao

In the realm of industrial coatings, high heat powder coatings have long been celebrated for their ability to withstand elevated temperatures while maintaining aesthetic appeal and functionality. However, as industries push the boundaries of performance, the demands on these coatings have grown exponentially. This has led to significant advancements in material science, with nanotechnology emerging as a transformative force in enhancing the thermal resistance and durability of high heat powder coatings.

Understanding High Heat Powder Coatings

High heat powder coatings are specialized coatings designed to endure temperatures that often exceed 200°C (392°F). These coatings are widely used in automotive parts, exhaust systems, industrial machinery, and cookware, where exposure to intense heat is routine. Typically, these coatings are formulated with polymers that can resist thermal degradation, ensuring longevity and maintaining their finish in harsh thermal environments.

The Challenge: Enhancing Thermal Resistance and Durability

Despite their capabilities, traditional high heat powder coatings face limitations. Prolonged exposure to extreme temperatures can lead to degradation, including cracking, fading, and loss of adhesion. Additionally, mechanical wear and environmental factors like UV radiation and chemical exposure can further reduce the life span of these coatings.

To address these challenges, researchers and manufacturers have been exploring ways to improve the intrinsic properties of these coatings without compromising on safety, cost-effectiveness, or environmental impact.

The Role of Nanotechnology in Coating Innovation

Nanotechnology involves manipulating materials at the nanometer scale, which is about 1 to 100 nanometers-an incredibly small scale where the physical and chemical properties of materials can differ significantly from their larger-scale counterparts. When integrated into coatings, nanoparticles can dramatically enhance performance by providing greater strength, increased thermal stability, and improved resistance to environmental degradation.

How Nanotechnology Enhances Thermal Resistance

Improved Heat Dissipation: Nanoparticles such as graphene, carbon nanotubes, and nanoclays have exceptional thermal conductivity. When these nanoparticles are incorporated into powder coatings, they facilitate better heat distribution across the coated surface, reducing localized thermal stress and enhancing the overall heat resistance.

Thermal Barrier Formation: Certain nanoparticles can create a barrier effect, limiting heat transfer to the substrate beneath the coating. For example, ceramic nanoparticles like alumina or zirconia can form a protective layer that withstands high temperatures and prevents the underlying material from overheating.

Reduction of Thermal Degradation: Nanoparticles help in stabilizing the polymer matrix at high temperatures by inhibiting free radical formation and delaying oxidation processes. This ensures that the coating maintains its structural integrity and appearance for longer periods under severe thermal conditions.

Enhancing Durability Through Nanotechnology

Mechanical Strength and Scratch Resistance: Nanoparticles enhance the mechanical properties of powder coatings, making them more resistant to scratches, impacts, and abrasion. For instance, incorporating silica or titanium dioxide nanoparticles can increase the hardness and toughness of the coating.

UV and Weather Resistance: Nanotechnology can also boost resistance to UV radiation by incorporating UV-absorbing nanoparticles. This prevents degradation caused by sunlight exposure, which is crucial for coatings exposed to outdoor environments.

Chemical Resistance: Nanoparticles can improve resistance to chemicals and corrosion, enhancing the coating’s lifespan in aggressive industrial or marine environments.

Real-World Applications and Benefits

The integration of nanotechnology into high heat powder coatings has opened new avenues across diverse industries. Automotive manufacturers benefit from coatings that protect engine parts from intense heat and extend maintenance intervals. Industrial equipment exposed to high temperatures like furnaces and boilers now enjoy coatings that reduce thermal wear and energy loss. Even consumer goods such as cookware and appliances see enhanced aesthetics and longevity thanks to these advancements.

Beyond performance, nanotechnology-enhanced coatings contribute to sustainability. Longer-lasting coatings mean fewer recoating jobs and less waste. Improved thermal management in industrial settings can also lead to energy savings, reducing the overall environmental footprint.

Challenges and Future Directions

While the advantages are significant, integrating nanotechnology into powder coatings is not without challenges. Ensuring uniform dispersion of nanoparticles within the coating matrix is critical to performance and can be technically demanding. Additionally, the health and environmental impacts of nanoparticles necessitate careful evaluation and regulatory compliance.

Looking ahead, ongoing research aims to develop multifunctional coatings that not only offer superior heat resistance and durability but also self-healing properties, anti-fouling capabilities, and enhanced aesthetic customization. The convergence of nanotechnology with other advanced materials and smart coating technologies promises a new era in surface protection and performance.

Conclusion

The integration of nanotechnology marks a significant leap forward in the evolution of high heat powder coatings. By enhancing thermal resistance and durability, nanotechnology ensures these coatings meet the growing demands of modern industries. As research continues to unlock new potentials, we can anticipate coatings that are not only more resilient and efficient but also smarter and more sustainable, securing their role in high-performance applications for years to come.

For professionals and businesses operating in high-temperature environments, embracing nanotechnology-enhanced high heat powder coatings is not just an option-it’s a strategic imperative to stay ahead in performance, sustainability, and innovation.

Explore Comprehensive Market Analysis of High Heat Powder Coatings Market

SOURCE-- @360iResearch

Subscribe to my newsletter

Read articles from Pranali Baderao directly inside your inbox. Subscribe to the newsletter, and don't miss out.

Written by