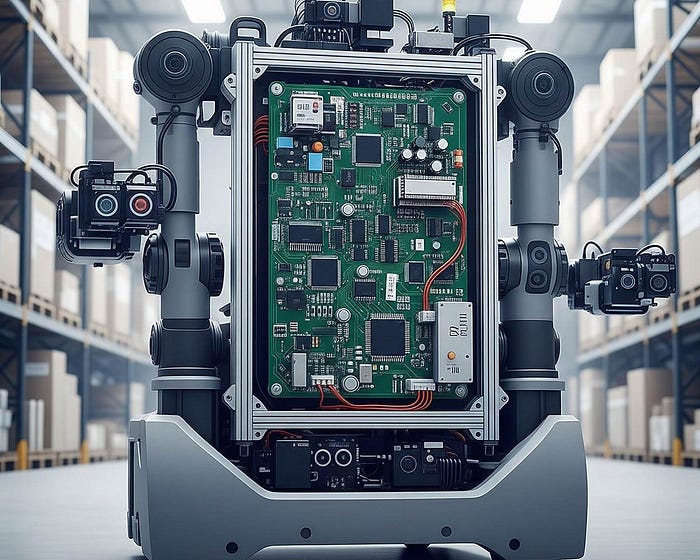

The Future of Warehouse Robots: AI Meets Electronics Design

Auckam

Auckam

The future of warehouse robots lies in the powerful fusion of AI integration and advanced electronics design — enabling smarter, faster, and more autonomous logistics operations. Electronics design ensures robots are compact, reliable, and capable of processing massive amounts of real-time data, while AI adds the intelligence to learn, adapt, and optimize warehouse tasks like sorting, picking, and navigating.

If you’re looking to understand what’s driving the next wave of innovation in warehouse automation, this article explains how AI and electronics are shaping the most efficient, intelligent robots ever built for industrial logistics.

Why AI and Electronics Design Are Game Changers for Warehouse Robots

Warehouses are fast-paced environments where precision, speed, and adaptability are critical. Traditional automation helped, but it lacked flexibility. Today, AI-driven warehouse robots powered by advanced electronics design are bridging that gap.

Here’s how the synergy works:

Electronics design enables lightweight, high-performance robotic systems with smart sensors, efficient power management, and robust connectivity.

AI integration processes that data to make decisions, learn from patterns, and continually improve task efficiency.

Together, they create autonomous systems capable of handling unpredictable inventory challenges in real time — faster and more reliably than ever.

Core Technologies Behind Modern Warehouse Robots

1. Smart Electronics Design

At the heart of every capable warehouse robot is a custom-designed electronic system, which includes:

Embedded microcontrollers and PCBs that control movement and communication

Sensor arrays for object detection, spatial awareness, and load tracking

Battery and power systems optimized for long shifts and fast recharging

Wireless modules for seamless data flow and remote updates

Electronics design focuses on reliability, low power consumption, and miniaturization — making robots both powerful and space-efficient.

2. AI Integration

AI gives robots the intelligence they need to:

Identify and classify objects with computer vision

Plan routes dynamically using real-time mapping and SLAM (Simultaneous Localization and Mapping)

Predict demand and optimize picking paths

Detect anomalies or safety risks without human intervention

This AI capability is only possible when backed by well-integrated, high-speed electronics that deliver real-time data and process it on-board or via edge computing.

Key Applications in Warehouses

Autonomous Mobile Robots (AMRs)

AI-powered AMRs use advanced sensors and AI algorithms to navigate warehouse floors, avoiding obstacles, rerouting in real-time, and managing deliveries.

Electronics role: Precise motor control, LiDAR/ultrasonic sensor support, real-time feedback, and robust safety circuits.

Robotic Picking Systems

Robots with grippers or suction arms can now pick and sort items of various shapes, guided by AI vision systems.

Electronics role: High-speed processors, smart camera modules, and force-sensitive feedback loops.

Inventory Monitoring Robots

Some robots autonomously scan shelves for stock levels, damaged goods, or misplaced items.

Electronics role: Imaging sensors, data logging circuits, and wireless sync with warehouse databases.

Benefits of AI + Electronics in Warehouse Robots

Greater Efficiency: AI algorithms optimize paths, reduce downtime, and adapt to demand.

Higher Accuracy: Fewer picking or sorting errors thanks to smart sensing and decision-making.

Scalability: Modular electronics design makes it easier to upgrade or expand systems.

24/7 Operation: Smart electronics allow continuous performance with minimal maintenance.

Reduced Labor Costs: Automation reduces reliance on manual labor for repetitive tasks.

Challenges in Design and Integration

While the benefits are clear, building next-gen warehouse robots isn’t without challenges:

Power constraints: AI processing requires energy; electronics must balance performance with battery life.

Sensor fusion complexity: Integrating multiple sensors into one coherent decision-making unit is tricky.

Thermal management: AI chips and motors generate heat, requiring clever thermal design.

Cybersecurity: Wireless communication and AI models must be protected from external threats.

These issues highlight the importance of precise, efficient electronics design and secure, robust AI models.

Future Trends to Watch

Edge AI for Faster Decisions

Instead of sending data to the cloud, AI processing is moving closer to the source (onboard). This requires faster processors and optimized electronics design to deliver near-instant results.

Swarm Robotics

Using multiple robots that coordinate like a hive mind, enabled by AI and synchronized electronics, to cover large warehouse spaces efficiently.

Predictive Maintenance

AI models will monitor wear-and-tear data from sensors to predict breakdowns before they happen — enabled by electronics that track vibration, temperature, or usage cycles.

Interoperability Standards

Future electronics design will focus on plug-and-play compatibility, allowing various robots to work in harmony across brands and platforms.

Real-World Example: AI-Powered Fulfillment Centers

Major players like Amazon and Alibaba already deploy hundreds of AI-integrated warehouse robots designed with advanced electronics systems. These robots:

Navigate high-density shelf areas

Communicate with human operators and other robots

Pick, sort, and deliver packages continuously

Adapt operations based on live order data

This synergy between electronics design and AI has helped these companies achieve previously impossible levels of speed and accuracy.

Final Thoughts

The future of warehouse robots is already taking shape — and it’s built on two pillars: brilliant electronics design and seamless AI integration. Together, they unlock the full potential of automation, allowing warehouse robots to think, adapt, and perform with superhuman precision.

For logistics leaders, engineers, and businesses looking to stay competitive, investing in this technology isn’t optional — it’s a strategic advantage. As innovation accelerates, expect to see even more intelligent, flexible, and efficient warehouse robots shaping the next generation of industrial success.

Subscribe to my newsletter

Read articles from Auckam directly inside your inbox. Subscribe to the newsletter, and don't miss out.

Written by