Beyond Machines: How IoT Is Reshaping Modern Manufacturing

Sarah R. Weiss

Sarah R. Weiss

Manufacturing has entered the smart era. With IoT and cloud-led technologies, today’s production lines are no longer reactive — they’re predictive, intelligent, and deeply connected.

Understanding Real-Time Monitoring for Smart Manufacturing Solutions

IoT-integrated production monitoring collects real-time equipment data and stores it securely in the cloud. Combined with AI-powered analytics, this enables manufacturers to track performance, monitor conditions, and detect issues before they escalate, ensuring smooth workflows and minimal downtime.

Without real-time monitoring, factories face inefficiencies, missed maintenance, and forecasting errors. Cloud-led IoT systems address this by providing comprehensive visibility, encompassing everything from machine health to environmental metrics such as temperature and humidity.

What Is Real-Time Monitoring in Smart Manufacturing?

It’s the fusion of IoT sensors and cloud analytics, creating a smart environment where data flows instantly from machines to dashboards. These systems detect anomalies, optimize resources, and help operators take immediate action. With devices monitoring every metric — like equipment status and worker performance — real-time control becomes the new normal.

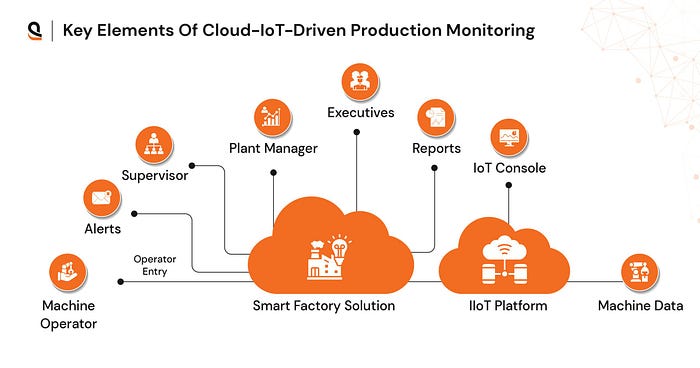

Key Elements of a Smart Production Monitoring System

Key Elements of a Smart Production Monitoring System

IoT for seamless data collection

Cloud for scalable storage and remote access

Analytics platforms to transform raw data into insights

Dashboards for easy data visualization

Monitoring devices for tracking every moving part

Significant Impact of Cloud and IoT in Manufacturing

According to McKinsey, the Internet of Things (IoT) could generate $1.2 to $3.7 trillion per year in manufacturing impact by 2025. Deloitte also reports a 70% reduction in equipment breakdowns and 25% lower maintenance costs from predictive systems.

Top Benefits of Integrating IoT and Cloud in Manufacturing

✅ Minimized Downtime & Predictive Maintenance

IoT sensors track equipment health, while AI forecasts failures early, reducing costly breakdowns and enabling smarter scheduling.

✅ Enhanced Production Efficiency

Smart dashboards and analytics identify bottlenecks, improve machine performance, and eliminate idle time across the production line.

✅ Real-Time Quality Control

Computer vision and sensor-based quality checks detect defects during production, ensuring consistency and minimizing rework.

✅ Better Supply Chain & Inventory Management

IoT-enabled inventory tracking prevents overstock, stockouts, and delays, boosting supply chain agility and reducing excess costs.

Subscribe to my newsletter

Read articles from Sarah R. Weiss directly inside your inbox. Subscribe to the newsletter, and don't miss out.

Written by

Sarah R. Weiss

Sarah R. Weiss

I share insights on Software Development, Data Science, and Machine Learning services. Let's explore technology together!