Dental Implant Drills as Surgical Instruments

Grey Medical

Grey MedicalThe world of dentistry has witnessed significant advancements over the years, and dental implantology stands out as one of its most transformative fields. Central to the success of this practice is a critical tool—the dental implant drill. Precision, efficiency, and innovation define these surgical instruments, and their evolving design continues to shape their indispensable role in modern dental procedures. From enhancing patient outcomes to enabling meticulous surgical precision, dental implant drills are a fundamental component of contemporary dental care.

The Importance of Dental Implant Drills in Surgical Procedures

Dental implant drills hold a pivotal place in the implementation of oral implants, serving as tools that prepare the jawbone to receive implants securely and effectively. Their primary function is to create a cylindrical channel in the bone that accommodates the implant, ensuring it integrates seamlessly with the surrounding bone tissue—a critical factor known as osseointegration.

The success of dental implant surgeries relies heavily on the precision with which these drills operate. Poor drilling techniques or subpar instruments can compromise the stability of the implant and, in severe cases, impact long-term patient outcomes. By enabling a controlled and precise approach, high-quality drills minimise trauma to the surrounding bone and soft tissues. This not only reduces post-surgical discomfort but also fosters quicker recovery.

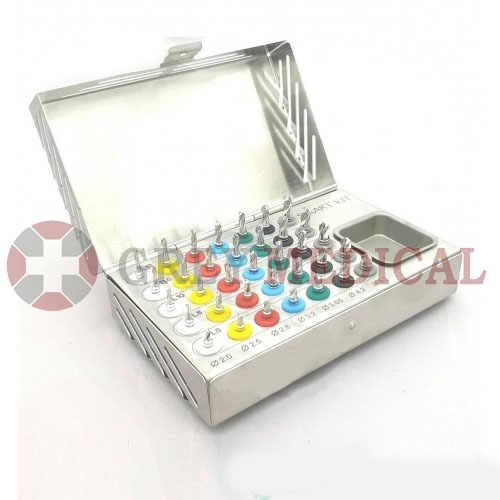

Beyond mechanical accuracy, the sterilisation and durability of dental implant drills are non-negotiable. Their ability to remain sterile and withstand repeated use in high-pressure surgical instrument environments makes them an essential part of a dental professional’s toolkit, ensuring both patient safety and procedural efficiency.

The Role of Precision in Patient Outcomes

One of the standout attributes of dental implant drills is their ability to operate with near-perfect precision. These tools are meticulously engineered to allow fine-tuned control, assisting surgeons in navigating the inherently delicate structures of the jawbone. Bone density, nerves, and sinuses vary from patient to patient, making a universal approach untenable. Dental implant drills, paired with advanced diagnostic tools, empower dentists to customise their approach for individual anatomy.

This precision extends beyond the surgical process. Accurate drilling reduces the risk of complications such as thermal bone damage, which can occur due to excessive heat during drilling. The prevention of such issues is achieved through features like internal irrigation systems that deliver a constant flow of cooling fluid. This cooling action maintains optimal temperatures throughout the procedure, preserving bone vitality and contributing to the longevity of the implant.

For patients, the benefits are manifold. High-precision instrumentation translates to shorter surgical durations, fewer risks of errors, and a smoother recovery. These factors culminate in improved satisfaction and trust among patients, reinforcing the importance of reliable and advanced dental tools.

Advancements in Dental Implant Drill Design and Technology

Dental implant drills today are far removed from their earlier iterations. Decades of innovation have resulted in a class of instruments that incorporate cutting-edge technology for optimal performance. The ergonomic design of modern drills allows surgeons to maintain steadiness and comfort during prolonged procedures, while lightweight materials reduce hand fatigue.

Technological adjuncts like computer-guided surgery have further elevated the relevance of implant drills. With the aid of digital imaging and CAD/CAM (computer-aided design and computer-aided manufacturing) systems, surgeons can pre-plan the exact positioning of the implant. This level of precision ensures that the drill cuts through the bone following an exact path determined by the surgical plan. Such advancements eliminate guesswork, improving both the predictability and reliability of the implant’s placement.

Another noteworthy innovation is the development of drills that are compatible with various implant systems. This enables clinics to cater to a wide range of patient needs, providing versatility without compromising on quality. Coatings such as diamond-like carbon (DLC) or titanium nitride enhance the lifespan of the drills, making them both cost-effective and high-performing.

Additionally, advancements in sterilisation techniques have accompanied technological progress. Modern drills are designed for easy cleaning and sterilisation, an essential consideration for meeting stringent hygienic standards in dental surgery.

The Significance of Dental Implant Drills in Modern Dentistry

Dental implant drills are far more than mechanical tools. They embody the precision, care, and innovation that define modern dentistry. With their integral role in ensuring successful implant procedures, they directly influence the confidence dentists place in their craft and the comfort patients experience during their treatment journeys.

The continuous evolution of dental implant drill technology signals a future where procedures will only become safer, faster, and more patient-centred. From the cutting-edge materials used in their construction to the integration with digital tools, the trajectory of these instruments highlights a commitment to better outcomes in dental care.

Ultimately, dental implant drills are not just instruments—they are enablers of transformation. They open doors to improved oral health, enhanced aesthetics, and, most importantly, restored confidence for countless individuals seeking dental implant solutions. This blend of innovation and precision underscores their irreplaceable value in the toolkit of any modern dental professional.

Subscribe to my newsletter

Read articles from Grey Medical directly inside your inbox. Subscribe to the newsletter, and don't miss out.

Written by