Smart Factory Market: HMI’s Rise as the Most Lucrative Emerging Tech

Georgie Bill

Georgie BillThe global smart factory market was valued at approximately USD 154.89 billion in 2024 and is projected to reach USD 272.64 billion by 2030, growing at a compound annual growth rate (CAGR) of 10.0% from 2025 to 2030. The market's growth is primarily driven by the increasing demand for automation and digital transformation, which enhance operational efficiency and reduce costs for manufacturers.

Additionally, the growing focus on energy efficiency and sustainability, along with advancements in technologies such as IoT, AI, and robotics, is propelling the adoption of smart factory solutions across various industries. The integration of artificial intelligence (AI) and machine learning (ML) technologies is facilitating smarter decision-making and predictive maintenance, creating lucrative opportunities for the smart factory industry in the coming years.

The rising demand for automation and digital transformation across sectors is prompting companies to enhance operational efficiency while lowering costs. Governments worldwide are promoting initiatives that support the adoption of Industry 4.0 technologies, which encompass advanced manufacturing systems, robotics, and IoT solutions. Furthermore, increasing energy costs and environmental regulations are encouraging manufacturers to adopt sustainable practices, leading to a greater emphasis on energy efficiency and resource optimization in production processes, thereby driving the smart factory industry.

Order a free sample PDF of the Smart Factory Market Intelligence Study, published by Grand View Research.

Key Market Trends & Insights

The Asia Pacific region is expected to experience the highest CAGR of over 11% from 2025 to 2030, largely due to rapid industrialization and significant government support for smart manufacturing initiatives. The growing demand for efficient production processes and high-quality products is fueling investments in smart factories across APAC, positioning it as a leader in the global smart manufacturing landscape.

By technology, the distributed control systems (DCS) segment held the largest revenue share of over 16% in 2024, thanks to its critical role in enhancing process control and operational efficiency across various industries. The growth in this segment is driven by the increasing adoption of automation technologies and the need for sophisticated control mechanisms in complex manufacturing environments.

In terms of field devices, the industrial robots segment accounted for the largest revenue share in 2024, driven by the rising demand for automation across various industries. With a projected market value of approximately USD 16.89 billion, the industrial robotics market is benefiting from advancements in artificial intelligence and digital automation technologies, which enhance operational efficiency and productivity.

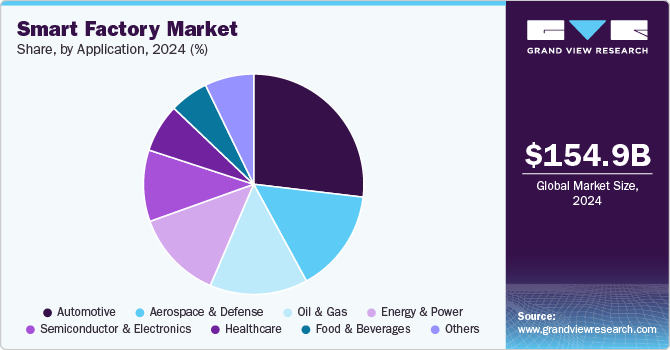

By application, the automotive segment captured the largest revenue share in 2024, primarily due to the industry's rapid adoption of automation and advanced manufacturing technologies. As automakers increasingly integrate smart factory solutions to boost production efficiency, reduce costs, and improve product quality, investments in robotics, IoT, and data analytics are becoming essential.

Market Size & Forecast

2024 Market Size: USD 154.89 Billion

2030 Projected Market Size: USD 272.64 Billion

CAGR (2025-2030): 10.0%

Asia Pacific: Largest market in 2024

Key Companies & Market Share Insights

Key players in the market include Rockwell Automation, Inc. and General Electric Company, among others.

Rockwell Automation, Inc. is a leading American company specializing in industrial automation and digital transformation technologies. It serves diverse sectors such as aerospace, automotive, food and beverage, and life sciences. The company offers a comprehensive range of products and services, including connected components, control systems, and advanced software solutions like FactoryTalk. Rockwell is recognized for its leadership in manufacturing execution systems (MES) and its innovative approaches to integrating AI and IIoT technologies into smart manufacturing processes.

General Electric Company (GE) is a multinational conglomerate with a strong focus on industrial automation through its Digital Industries division. The company leverages its expertise in data analytics and connectivity to provide solutions that enhance operational efficiency across industries, including aviation, healthcare, and renewable energy. GE emphasizes integrating advanced technologies such as artificial intelligence and machine learning to optimize manufacturing processes.

Emerging players in the smart factory market include Danfoss and Fanuc Corporation.

Danfoss provides energy-efficient and climate-friendly solutions, focusing on integrating smart manufacturing technologies to enhance operational efficiency while minimizing environmental impact. The company invests significantly in research and development to explore innovative technologies that incorporate automation and data-driven decision-making.

Fanuc Corporation specializes in robotics and factory automation. The company places a high emphasis on continuous innovation in smart manufacturing technologies, including advanced robotics and AI integration, which allows it to maintain a competitive edge. Fanuc's focus on enhancing production efficiency through automation and its commitment to developing cutting-edge solutions position it as an emerging player in the evolving landscape of smart factories.

Key Players

Siemens AG

GE Vernova (General Electric Company)

Rockwell Automation, Inc.

Schiender Electric

Honeywell International, Inc.

ABB Ltd.

Mitsubishi Electric Corporation

Fanuc Corporation

Danfoss

Explore Horizon Databook – The world's most expansive market intelligence platform developed by Grand View Research.

Conclusion

The smart factory market is poised for significant growth, driven by the increasing demand for automation and digital transformation across various industries. As companies seek to enhance operational efficiency and reduce costs, the integration of advanced technologies such as IoT, AI, and robotics will play a crucial role in shaping the future of manufacturing. With the Asia Pacific region leading the market and continued investments in smart manufacturing initiatives, the smart factory sector is well-positioned for expansion and innovation in the years ahead. As sustainability and energy efficiency become more critical, the adoption of smart factory solutions will likely accelerate, driving further advancements in this dynamic industry.

Subscribe to my newsletter

Read articles from Georgie Bill directly inside your inbox. Subscribe to the newsletter, and don't miss out.

Written by